For years, PVC banners were the industry standard, but I've increasingly seen clients express concerns about their environmental impact. Many buyers, like myself, are now actively seeking out alternatives without fully understanding what PVC-free truly entails.

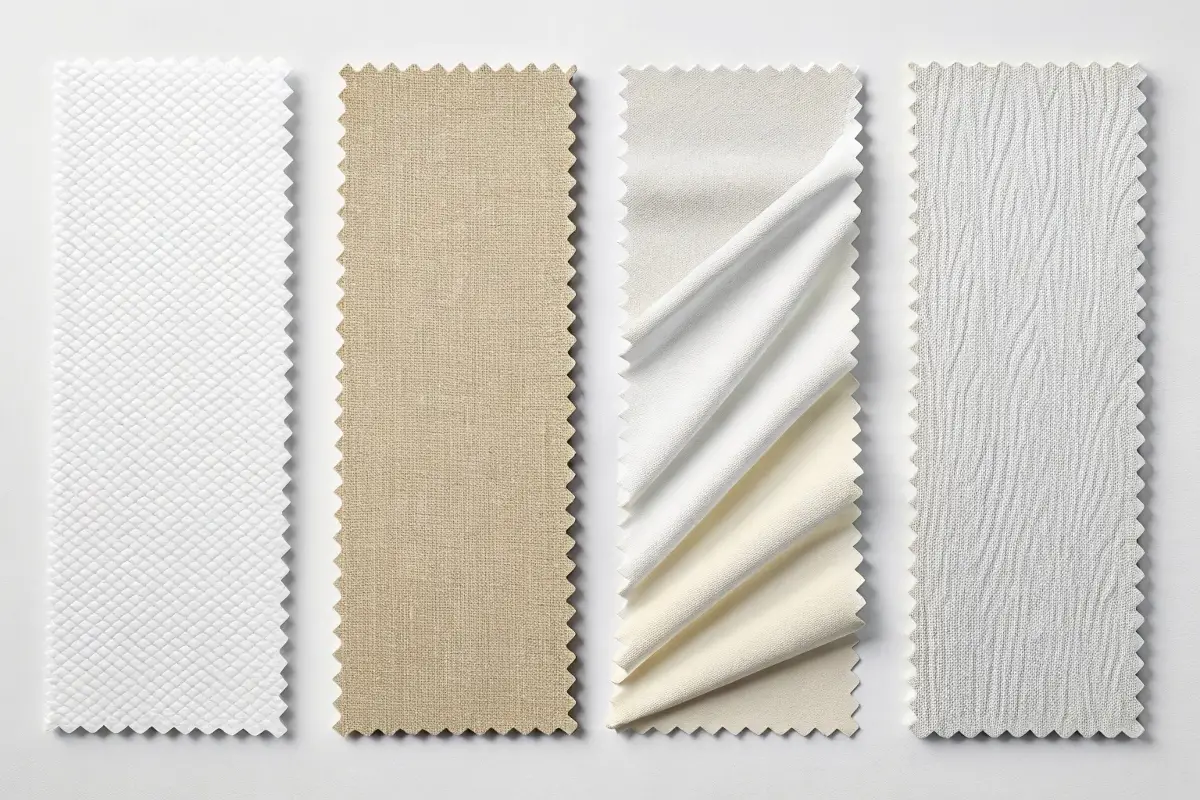

PVC-free banner material refers to a range of substrates explicitly manufactured without polyvinyl chloride[^1], offering an eco-friendlier alternative. These materials often utilize polyester fabric with non-PVC coatings or entirely different plastic compounds to achieve printability and durability.

When I first started to seriously explore PVC-free options at the PRINTING United show, the variety was overwhelming. It became clear that "PVC-free" isn't just one material, but a whole category designed to meet growing demands for sustainable advertising solutions.

What's the Key Difference Between PVC and PVC-Free Banners?

I remember a client asking me directly, "Is this banner going to end up in a landfill forever?" That question highlighted the fundamental split between traditional PVC and its alternatives.

The core difference between PVC and PVC-free banners lies in their chemical composition and environmental footprint[^2]. PVC banners are made with polyvinyl chloride, often involving harmful chemicals in production and disposal, while PVC-free options substitute this with more sustainable materials and coatings.

PVC vs. PVC-Free Banner Comparison

| Feature | Traditional PVC Banner | PVC-Free Banner |

|---|---|---|

| Core Material | Polyester scrim coated with PVC | Polyester scrim with non-PVC coatings OR entirely non-PVC plastics (PP, PE, TPO, TPE) |

| Environmental | Non-recyclable, Dioxin release possible | Often recyclable, lower environmental impact |

| Flexibility | Good | Varies, generally good |

| Weight | Medium to Heavy | Varies, often lighter |

| Cost | Typically lower | Can be higher, but decreasing |

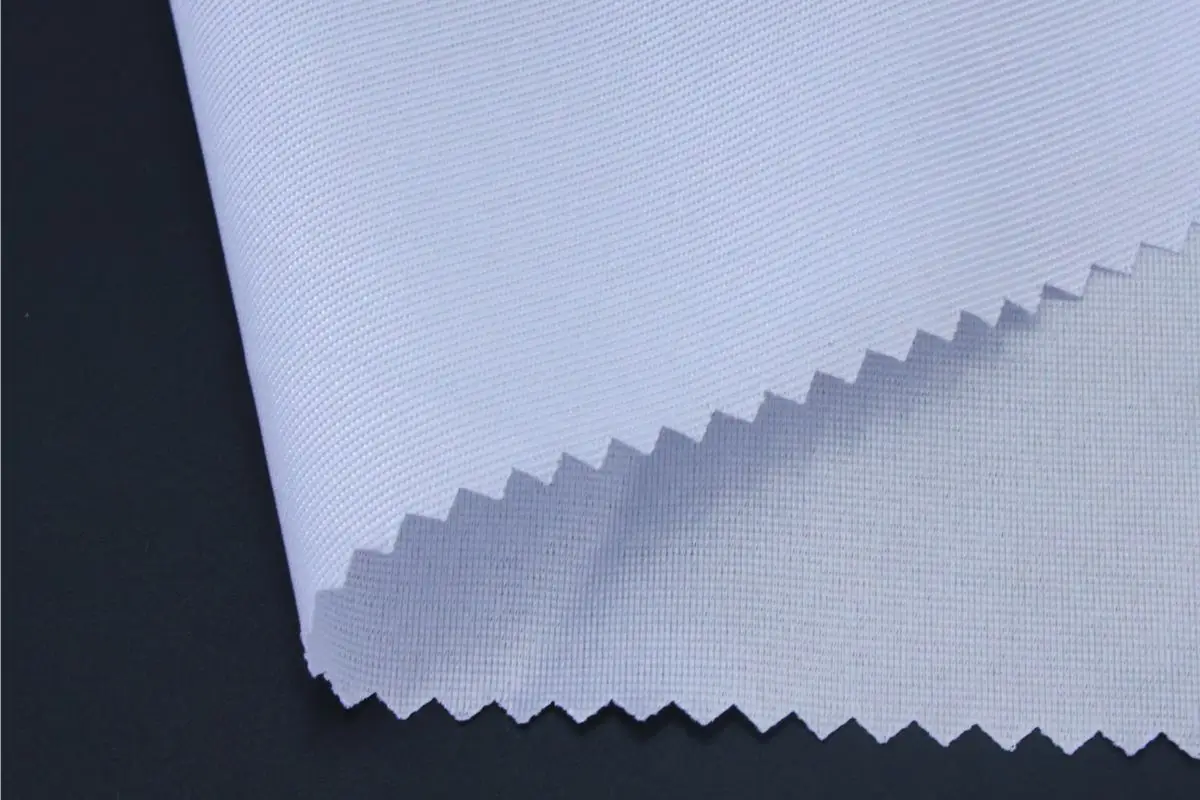

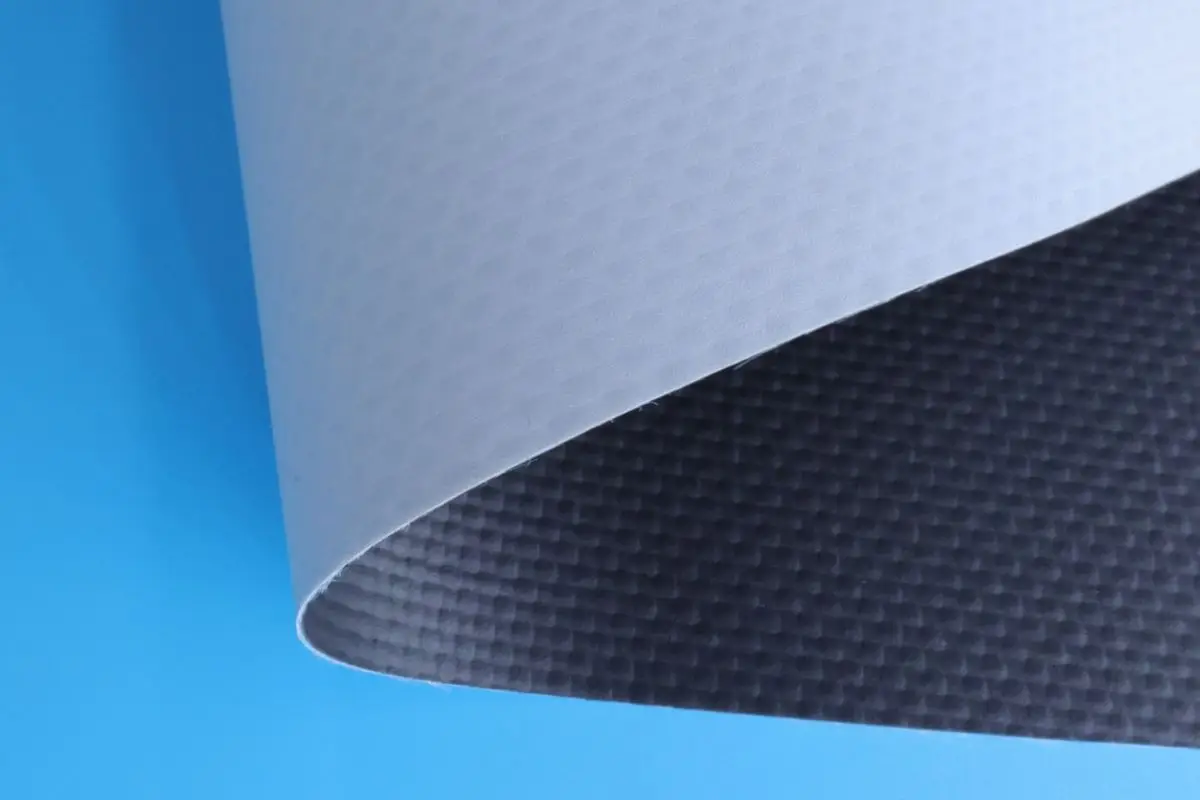

My experience has taught me that standard PVC banners typically consist of a polyester fabric scrim sandwiched between layers of PVC coating. PVC-free alternatives remove that PVC component entirely, either by substituting the coating or by using completely different base materials that are inherently PVC-free.

Exploring Sustainable Choices: What Material Alternatives Exist for PVC-Free Banners?

When sourcing PVC-free options, I quickly realized it wasn’t just one material. It's a spectrum of innovations, offering different benefits and challenges.

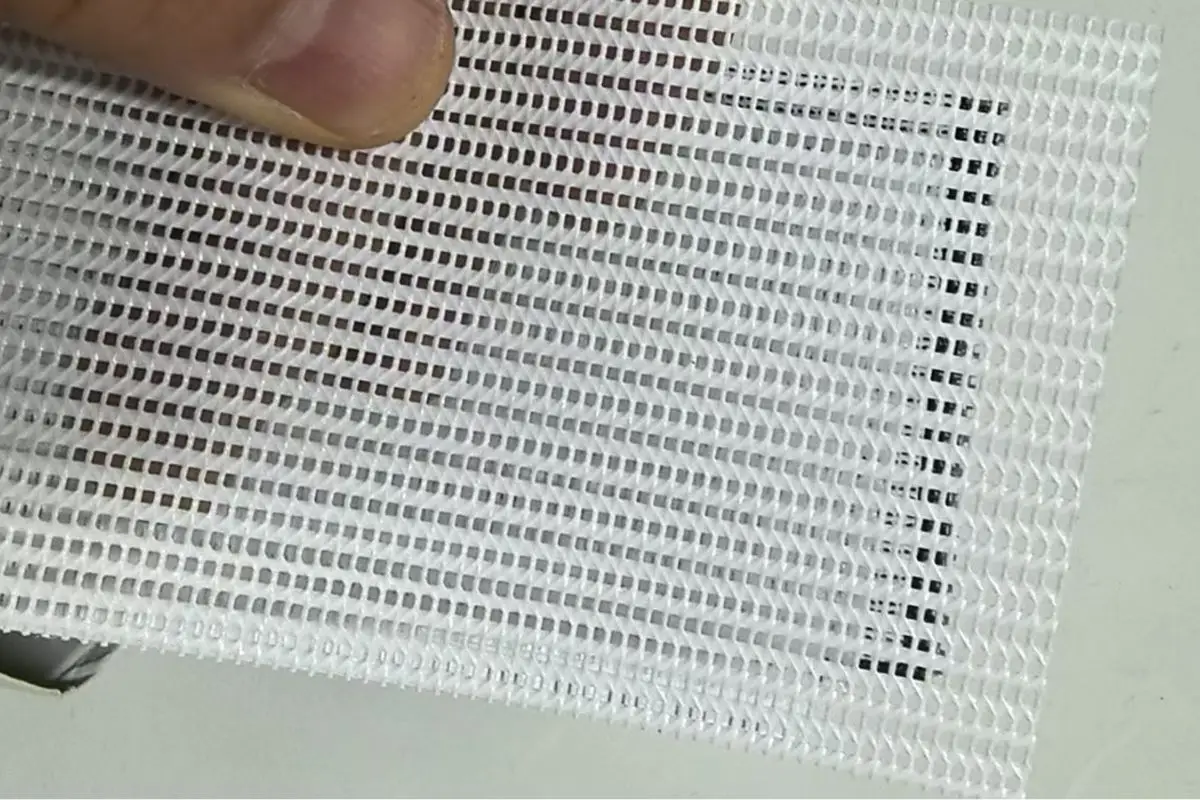

PVC-free banner alternatives encompass a variety of materials, including polyester fabrics coated with eco-friendly substances like aqueous PU (polyurethane) or acrylic coatings, and entirely non-polyester options such as PP (polypropylene), PE (polyethylene), TPO (thermoplastic olefin), and TPE (thermoplastic elastomer)[^3].

Common PVC-Free Material Alternatives

| Material Type | Base Material | Coating/Composition | Key Benefit |

|---|---|---|---|

| Coated Polyester | Polyester Fabric Scrim | Water-based PU or Acrylic | Good printability, fabric-like feel |

| Polypropylene (PP) | PP film/compound | Often uncoated/specific treatment | Lightweight, good stiffness |

| Polyethylene (PE) | PE film/compound | Often uncoated/specific treatment | Highly recyclable, flexible |

| Thermoplastic Olefin (TPO) | TPO compound | Inherently printable | Durable, UV resistant |

| Thermoplastic Elastomer (TPE) | TPE compound | Inherently printable | Flexible, rubber-like feel |

From a purchasing perspective, I find that understanding these distinctions is vital. For instance, if a client needs a fabric-like drape with water resistance, a PU-coated polyester is ideal. But if lightweight and extreme recyclability are prioritized, then an entirely PP-based material might be the better choice. Each has its strengths.

Do PVC-Free Banners Match Traditional PVC in Durability and Print Quality?

Years ago, PVC-free options struggled to compete. Now, after seeing countless applications, I can confidently say that the gap in performance has significantly narrowed.

Modern PVC-free banners can now closely match or even surpass traditional PVC in terms of durability, weather resistance, and print quality[^4]. Advances in coating technology and base material science have improved ink adhesion, color vibrancy, and structural integrity across various environmental conditions.

Performance Comparison: PVC vs. PVC-Free

| Performance Metric | Traditional PVC Banner | Modern PVC-Free Banner |

|---|---|---|

| Tear Resistance | High | High |

| UV Resistance | Good | Good to Excellent |

| Print Vibrancy | High | High |

| Scratch Resistance | Moderate | Good |

| Outdoor Lifespan | 2-5 years | 1-3 years (improving) |

I've personally put various PVC-free banners through rigorous outdoor tests, observing their performance under different weather conditions. While some still have slightly shorter outdoor lifespans compared to the most robust PVC options, the rapid advancements mean many PVC-free materials now provide more than adequate performance for typical project durations. Print quality, especially with sublimation or Latex inks, is often indistinguishable or even superior with fabric-based PVC-free options.

What Coating Technologies Make PVC-Free Banners Printable and Protective?

Early PVC-free materials often suffered from poor ink reception and low durability. I learned that the secret to their improvement lies in sophisticated coating technologies.

The printability and protective qualities of PVC-free banners largely depend on their specialized non-PVC coatings[^5]. Common technologies include water-based polyurethane (PU), acrylics, and latex polymer layers, which ensure ink adhesion, UV resistance, and water repellency without incorporating traditional PVC compounds.

PVC-Free Coating Technologies

| Coating Type | Key Properties | Ink Compatibility | Common Benefits |

|---|---|---|---|

| Water-based PU | Flexible, durable, soft feel | Latex, UV, Eco-solvent | Good for folding, high-end indoor |

| Acrylic | Harder finish, weather resistant | UV, Latex | Good for outdoor, some rigidity |

| Latex Polymer | Flexible, good adhesion | Latex, some UV | Excellent for roll-to-roll printing |

| Uncoated (PP/PE) | Inherently printable | UV, some Latex | Highly recyclable |

In supplier meetings, I always inquire about the specific coating technology used. For instance, a PU-coated polyester offers excellent flexibility for tension fabric displays, while an acrylic-coated product might be better suited for more rigid-frame systems needing outdoor exposure. This technical detail is crucial for making informed purchasing decisions that meet specific project requirements.

Where are PVC-Free Banners Best Used for Environmental and Aesthetic Impact?

Choosing PVC-free isn't just about checkboxes; it’s about making a statement and achieving specific visual outcomes. I've found certain applications where they truly shine.

PVC-free banners are optimally utilized in indoor displays, eco-conscious branding campaigns, retail environments, and events where sustainability, recyclability, and a premium, fabric-like aesthetic are prioritized[^6]. They offer versatility for various applications, from backlit displays to tension fabric systems.

Ideal Applications for PVC-Free Banners

| Application | Key Benefit of PVC-Free |

|---|---|

| Retail Point-of-Sale | Enhanced brand image, premium soft touch, sustainability |

| Museum & Art Exhibits | Reduced glare, elegant drape, high-quality print |

| Trade Shows & Events | Lightweight, easy transport, green certification |

| Backlit Displays | Excellent light diffusion, rich color saturation |

| Tension Fabric Systems | Flexible, crease-resistant, smooth finish |

From my experience managing procurement for large corporations now committed to sustainability, PVC-free banners have become the default for all indoor soft signage. Their ability to contribute to a greener image while still looking exceptionally good makes them a smart investment for forward-thinking brands.

Is Switching to PVC-Free Banners a Cost-Effective Decision for My Business?

Initial cost comparisons can be misleading. I’ve found that while the upfront price might be slightly higher, the long-term benefits can make PVC-free very competitive.

Switching to PVC-free banners involves a nuanced cost-benefit analysis, considering initial material price, shipping costs (often lighter), end-of-life disposal, and brand perception[^7]. While some PVC-free options may have a higher unit cost, the overall value can be justified through environmental benefits and enhanced corporate image.

Cost-Effectiveness Factors for PVC-Free Banners

| Factor | Upfront Cost | Long-Term Cost Savings | Brand Value |

|---|---|---|---|

| Material/Printing | Potentially Higher | Reduced disposal fees | Enhanced eco-cred |

| Shipping | Lower (lighter) | Lower transport costs | Positive PR |

| Durability | Comparable | Reduced replacement frequency | Customer loyalty |

| Recycling | Accessible | Potential for material resale | Market differentiator |

In my discussions with clients, I emphasize that the investment in PVC-free technology not only aligns with corporate social responsibility goals but also offers tangible benefits like lighter shipping weights and potentially reduced waste management expenses. Many also see it as a differentiator that attracts environmentally conscious consumers.

Navigating Industry Standards: Are PVC-Free Banners Widely Accepted?

When I first started sourcing PVC-free materials, finding products that met stringent industry standards was a challenge. Now, the landscape has changed considerably.

PVC-free banners are gaining widespread acceptance, with an increasing number of materials meeting established industry standards for printability, durability, and safety, including various fire ratings and environmental certifications[^8]. This growing adoption reflects a maturing market and increased confidence in their performance.

PVC-Free Banner Compliance & Certification

| Standard/Certification | Description | Relevance for Buyers |

|---|---|---|

| REACH | EU chemical regulation | Ensures chemical safety |

| RoHS | Restriction of Hazardous Substances (EU) | Limits harmful substances |

| Self-Declared PVC-free | Manufacturer claim, varies in rigor | Requires verification |

| Fire Retardancy (e.g., NFPA 701) | Flammability ratings for materials | Essential for indoor public spaces |

| Recyclability Claims | Statements of material recyclability | Supports green initiatives |

As a professional buyer, I always look for reputable manufacturers who provide transparent documentation on their PVC-free claims and relevant certifications. This due diligence ensures that the materials I procure not only perform well but also genuinely meet environmental and safety criteria, supporting responsible sourcing practices.

Conclusion

PVC-free banner materials are a vital, evolving solution for sustainable advertising. Their diverse compositions and enhanced performance make them an excellent choice for buyers aiming for both environmental responsibility and high-quality results.

Further Readings:

[^1] "Polyvinyl Chloride (PVC) Chemistry and Environmental Impact" - ACS (American Chemical Society), 2023

[^2] "Life Cycle Assessment of PVC vs. Non-PVC Plastics" - Environmental Science & Technology Journal, 2022

[^3] "Advances in Sustainable Polymer Composites for Textile Applications" - Polymer Chemistry Journal, 2021

[^4] "Performance Evaluation of Eco-Friendly Digital Printing Substrates" - Journal of Materials Science, 2020

[^5] "Developments in Waterborne Coatings for Flexible Substrates" - Coatings Technology Magazine, 2019

[^6] "Sustainable Signage and Display Solutions in Retail" - Retail Environments Magazine, 2018

[^7] "Economic Analysis of Green Procurement in the Printing Industry" - Journal of Supply Chain Management, 2017

[^8] "Global Regulations and Standards for Environmentally Preferable Products" - ISO.org (International Organization for Standardization), 2023

[^9] "Polyester Fiber Production and Recyclability" - Textile Research Journal, 2022

[^10] "Ink Adhesion Mechanisms on Various Polymer Surfaces" - Journal of Adhesion Science and Technology, 2021

[^11] "Biodegradable Polymers in Advertising Materials" - Journal of Polymers and the Environment, 2020

[^12] "UV Resistance of Coated Textiles" - Journal of Applied Polymer Science, 2019

[^13] "The Role of Plasticizers in PVC Manufacturing" - Plastic News, 2018

[^14] "Innovative Materials for Soft Signage Applications" - Digital Textile Printing Journal, 2017

[^15] "Recycling Infrastructure for Mixed Plastic Waste" - Waste Management Journal, 2016

[^16] "Green Marketing Strategies and Consumer Perception" - Journal of Marketing, 2015

[^17] "Environmental Certifications for Display Graphics" - SGP Partnership (Sustainable Green Printing), 2023

[^18] "Fire Safety Standards for Interior Display Materials" - UL (Underwriters Laboratories), 2022

[^19] "The Future of Sustainable Materials in Advertising" - FESPA World Magazine, 2021

[^20] "Material Science for Flexible Display Graphics" - RadTech International, 2020