What is Inkjet Printable Permanent Adhesive Vinyl?

Are you struggling to find the right material for your printing needs? Many professional buyers like Mr. Watford overlook crucial details, getting stuck with products that seem similar but perform very differently.

Inkjet printable permanent adhesive vinyl is a versatile material I've seen used in countless applications, from outdoor signage to durable vehicle wraps. It's a type of flexible plastic film, often PVC based, designed to accept various inks from inkjet printers, and it comes with a strong adhesive backing for long-lasting applications.

I remember my early days at Shanghai Chungkong Ad-Mart Co., Ltd., helping clients understand the nuances of printable media. It was clear then, and remains true today, that understanding the core properties of a material like this vinyl is essential for achieving the best results and avoiding costly mistakes later on.

What is Permanent Adhesive Vinyl vs. removable, and which inks and printers can be used?

Are you uncertain about the main differences between permanent and removable adhesive vinyl, and which one is right for your project? Many of my partners, including Mr. Watford, often ask about these distinctions, along with compatible inks and printers.

Permanent adhesive vinyl forms a strong, long-lasting bond once applied. On the other hand, removable adhesive vinyl is designed for temporary applications, allowing for clean removal without leaving residue. The choice depends entirely on the application's intended lifespan and whether you need to reposition or remove the graphic later.

When I first started interacting with international clients like Manish Aggarwal from Mono Sign in India, one of the most common discussions we had revolved around the different adhesive types. It’s a fundamental choice that impacts the entire project.

To help illustrate the differences between permanent and removable vinyl, I've put together a table that breaks down their key characteristics and ideal uses. This clarity is something I always strive for, both in my manufacturing processes and in empowering my partners.

| Feature | Permanent Adhesive Vinyl | Removable Adhesive Vinyl |

|---|---|---|

| Adhesive Strength | Strong, long-term bond | Weaker, temporary bond |

| Longevity | Years, designed for durability | Weeks to months, designed for short-term |

| Residue Upon Removal | May leave residue or damage surface | Clean removal, minimal to no residue |

| Typical Applications | Vehicle wraps, outdoor signs, wall graphics, floor graphics | Retail promotions, temporary decals, interior wall art |

| Repositionability | Limited to none without damaging material or surface | Often repositionable during installation |

1 Many types of inks can be used with inkjet printable vinyl, including solvent, eco-solvent, UV, and latex inks. The specific ink type depends on your printer technology. For example, my company, Hangzhou Nuclear Coated Fabrics Co., Ltd., ensures our media performs consistently with printers like those made by HP, EFI, Epson, and Roland, which are popular with professionals like Mr. Watford. It is important to match the vinyl's coating to the ink for optimal adhesion, color vibrancy, and drying time.

What should be considered when choosing Inkjet Printable Permanent Adhesive Vinyl?

Are you aware that choosing the right inkjet printable permanent adhesive vinyl involves much more than just the initial price tag? Over my 15 years in this industry, I have seen many professionals overlook critical factors that impact overall project costs and success.

When I talk with our clients at nlsigns.com, or directly with partners I am helping set up flex banner production facilities, I always emphasize looking beyond just the product price. We need to consider overall costs, which include not only the material price but also printing costs, installation labor, and even potential waste.

I recall a conversation with Mr. Watford during a trade show. He mentioned how crucial it is for him to evaluate products not just on their specified features but on their real-world performance. He is right; a product’s perceived value can quickly diminish if it increases other operational costs.

Here are some key considerations I always discuss with my partners to ensure they make a truly informed decision. These factors are critical to evaluating the total cost of ownership, as Mr. Watford so keenly understands.

| Consideration | Impact on Overall Cost | My Advice |

|---|---|---|

| Color Vibrancy | Poor vibrancy requires higher ink loading, increasing ink costs and drying time. | Look for vinyl with excellent ink absorption and a bright white point. Test samples with your specific inks. |

| Drying Time | Slow drying extends production time, increasing labor costs and potentially delaying projects. | Choose fast-drying formulations. This speeds up production and reduces the risk of smudging. |

| Material Stiffness | Too flimsy, and one-person installation may require two, doubling labor costs. Too stiff, and it may not conform well. | Find a balance. For large graphics, a degree of stiffness aids handling but must remain conformable. |

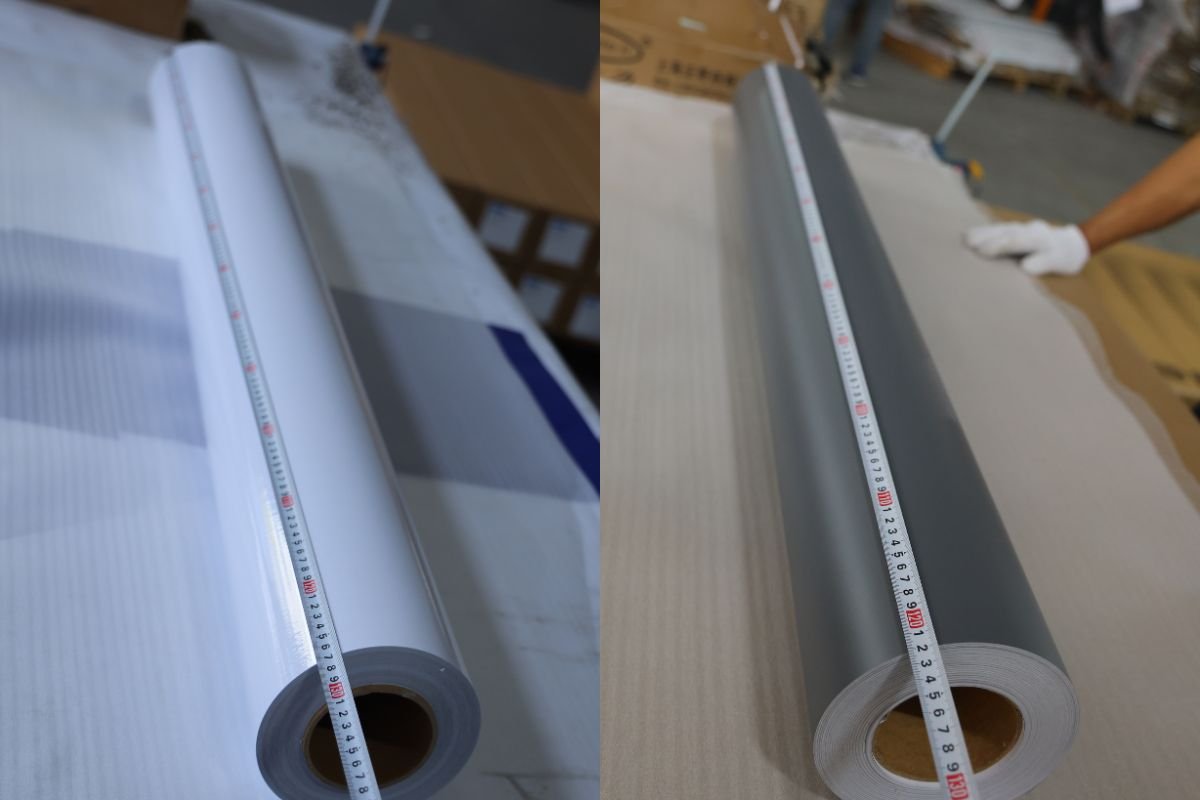

| Surface Smoothness | Imperfections lead to poor print quality, waste, and needing re-runs. | Inspect the material closely. A smooth surface ensures consistent ink application and sharp graphics. |

| Outdoor Durability | Short lifespan in outdoor use requires frequent replacement, increasing material and labor costs. | Look for UV resistance, waterproof properties, and temperature stability for long-term outdoor applications. |

How does vinyl’s pliability affect installation and durability?

Have you ever grappled with vinyl that refused to conform to complex curves or wrinkles easily during installation? Many customers, from seasoned installers to new entrepreneurs I've helped, often struggle with vinyl’s pliability, which can deeply influence both installation efficiency and the overall durability of the finished graphic.

Pliability—the material’s ability to bend and conform without breaking or deforming—is critical for professional results. Vinyl that is too stiff can be difficult to apply to irregular surfaces, leading to bubbles and poor adhesion, especially in cold weather. Conversely, vinyl that is too soft might stretch excessively, causing distortion or tearing during application and potentially reducing long-term durability.

When I work with my manufacturing team at Hangzhou Nuclear Coated Fabrics Co., Ltd., we meticulously test the flexibility and conformability of our coated technical textiles. I learned early on that even a slight difference in flexibility can make or break a project, particularly for challenging applications like vehicle wraps or corrugated sign boards. My long-standing partner, Mr. Watford, also stresses that material pliability is a key factor in his supplier evaluations, ensuring ease of application and longevity for his diverse clientele.

Understanding how pliability affects your projects is not just about avoiding frustration during installation; it's about guaranteeing the graphic’s longevity and maintaining quality. Here’s how these characteristics play out in real-world scenarios, and why striking the right balance is so important.

| Pliability Characteristic | Impact on Installation | Impact on Durability | My Recommendation |

|---|---|---|---|

| Too Stiff | Difficult to apply to curves, may bridge over indentations, prone to bubbling. | Tends to lift at edges on curved surfaces, susceptible to cracking in cold. | Best for flat, rigid surfaces like sign boards. Pre-heat for cold-weather applications. |

| Too Soft/Stretchy | Easy to overstretch and distort graphics, may wrinkle during handling. | Can shrink back over time, leading to gaps or exposed adhesive; less abrasion resistance. | Handle with care during installation. Best for applications needing high conformity, e.g., complex vehicle wraps. |

| Balanced Pliability | Conforms well to moderate curves and flat surfaces, easier to handle. | Good long-term adhesion, resists lifting and cracking, maintains graphic integrity. | Ideal for most general-purpose applications. Offers a good balance of ease of use and longevity. |

How do surface finish and coating quality impact print results and aesthetics?

Have you noticed how much the surface finish and coating quality of your inkjet printable permanent adhesive vinyl can drastically alter your print results and overall visual appeal? As a technophile focused on materials science, I constantly emphasize how these often-overlooked details are crucial for achieving vibrant, consistent colors and professional aesthetics.

The surface finish of the vinyl—whether it’s glossy, matte, or satin—directly affects how light interacts with your printed graphics. A glossy finish gives a vibrant, reflective look, often making colors pop, but it can also show glare. A matte finish reduces glare and fingerprints, offering a sophisticated, subdued appearance, though colors might seem slightly less intense. The coating quality, on the other hand, determines ink absorption, drying time, and color accuracy. A poor coating can lead to blotchy prints, slow drying, or colors that don't match your proofs, regardless of your ink quality.

In my manufacturing operations at Hangzhou Nuclear Coated Fabrics Co., Ltd., we dedicate significant resources to perfecting our coatings. I know first-hand that meticulous control over the coating process ensures our materials meet stringent global demands for vibrant color reproduction and consistent quality. This commitment directly addresses the needs of discerning buyers like Mr. Watford, who understands that the quality of print is not solely dependent on the printer or ink, but fundamentally on the media itself.

Here is a breakdown of how different surface finishes and coating qualities influence the end result, offering a clearer perspective on why these elements are so vital for any printing project.

| Characteristic | Impact on Print Quality | Impact on Aesthetics | My Recommendation |

|---|---|---|---|

| Glossy Finish | Produces vibrant colors, high contrast, sharp details. | Reflective, high-sheen appearance; can show glare and fingerprints; looks premium. | Best for vivid graphics, photos, or when you want a “wow” factor. Consider lighting environment. |

| Matte Finish | Reduces glare, softer colors, can enhance readability in brightly lit areas. | Non-reflective, subdued elegance; resistant to fingerprints; professional look. | Ideal for displays in well-lit environments, text-heavy graphics, or refined brand aesthetics. |

| Satin Finish | A balance between glossy and matte; good color vibrancy without excessive glare. | Smooth, low-sheen, sophisticated look; versatile for many applications. | A good all-rounder for when you can’t decide or need a balance of vibrancy and reduced glare. |

| High-Quality Coating | Even ink absorption, fast drying, precise color, excellent adhesion. | Sharp, unblemished graphics; consistent color across entire print. | Essential for all professional output. Ensures ink longevity and prevents bleeding or fading. |

| Low-Quality Coating | Blotchy prints, slow drying, color shifts, poor ink adhesion, premature fading. | Dull, inconsistent appearance; can lead to early print degradation. | Avoid cheap, inconsistent coatings. They lead to wasted time, ink, and material. |

Why is choosing an environmentally compliant inkjet vinyl crucial for modern businesses?

Are you aware of the growing demand for sustainable materials and how crucial it is for modern businesses to choose environmentally compliant inkjet vinyl? As a devoted family man and a father of two, I believe in nurturing curiosity and building a better future, which includes advocating for responsible manufacturing and product choices.

Choosing eco-friendly materials is more than just a trend; it reflects a commitment to global sustainability and can significantly enhance your brand image. Environmentally compliant vinyl often uses materials with lower Volatile Organic Compounds (VOCs)2, is free from harmful chemicals like phthalates3 or heavy metals, and in some cases, can even be biodegradable4. This helps reduce the environmental footprint of your business and aligns with the values of customers who are increasingly prioritizing sustainability.

When I connect with forward-thinking partners, especially those attending international exhibitions in China, I stress the importance of innovation and sustainability. Mr. Watford, for instance, explicitly looks for suppliers who offer cutting-edge solutions, including eco-friendly materials like biodegradable films and low-VOC inks. His philosophy underscores that procurement is about discovering value and managing risk, and ignoring environmental compliance certainly adds risk in today's market. Aligning with these values is not just good for the planet; it’s good for business.

Here's why prioritizing environmentally compliant inkjet vinyl is crucial for building a resilient, respected business in today’s marketplace. This approach mirrors my own desire to give back and empower partners worldwide through knowledge-sharing and sustainable practices.

| Aspect | Business Impact | My Perspective |

|---|---|---|

| Brand Reputation | Enhances public image, attracts environmentally conscious customers. | Investing in eco-friendly options builds trust and positions your brand as a responsible leader. |

| Market Compliance | Meets evolving regulations and industry standards, avoiding legal issues. | Proactive compliance with standards like REACH5 or RoHS6 ensures long-term market access and avoids penalties. |

| Employee Health | Reduces exposure to harmful chemicals, creating a safer work environment. | A healthier workplace translates to happier, more productive employees and reduced health-related costs. |

| Customer Demand | Appeals to a growing segment of consumers who value sustainability. | Fulfilling this demand helps secure new clients and strengthens relationships with existing ones, like Mr. Watford. |

| Innovation & Future-Proofing | Positions your business at the forefront of sustainable practices for future growth. | Embracing sustainable materials drives innovation and helps you stay competitive in a rapidly changing market. |

In conclusion, choosing inkjet printable permanent adhesive vinyl is a delicate balance of cost, performance, and impact. By carefully considering all factors, you ensure vibrant, durable results while making responsible choices for your business and the environment, mirroring my philosophy of empowering progress through thoughtful partnership.

Further readings

Inkjet Printers: Learn more about how inkjet printers work at Wikipedia. ↩

Volatile Organic Compounds (VOCs): Information on VOCs and their environmental impact can be found at EPA.gov. ↩

Phthalates: Learn about phthalates and health concerns at NIEHS.NIH.gov. ↩

Biodegradable Materials: General information on biodegradable materials can be found at Wikipedia. ↩

REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals): Official information on REACH regulations is available from the European Chemicals Agency (ECHA). ↩

RoHS (Restriction of Hazardous Substances): Learn about RoHS compliance from RoHS Guide. ↩