Frustrated by flex banner quality issues that delay projects or disappoint clients, costing you time and money? We understand the critical impact material problems have on your business and reputation, especially when managing complex supply chains like Mr. Watford.

Solving common flex banner material problems involves understanding root causes like frayed edges, surface stickiness, dull colors, or perceived weight discrepancies. My experience shows that proper material handling, tailored surface treatments, optimized printer settings, and precise quality control are key to overcoming these challenges and ensuring consistent, high-quality output for your valued customers.

In my years in the printable signage media industry as the founder of Hangzhou Nuclear Coated Fabrics Co., Ltd., I have encountered countless challenges with flex banner materials, from the simplest nuisance to complex technical headaches. I vividly remember troubleshooting issues on-site, sometimes late into the night, just to ensure a client's project was perfect. These experiences taught me that understanding common problems is the first step towards robust solutions and building reliable products, much like the precision-engineered printers Mr. Watford relies on. Let's dive into some of the most frequent material problems and how we can tackle them together. This journey of knowledge-sharing is central to empowering our partners worldwide.

Are Frayed Edges on Flex Banners a Threat to Your Printing Equipment?

Annoyed by unsightly frayed edges on your flex banners that compromise aesthetics and productivity? This common issue, especially with cold laminated banners, can actually cost you more than just a ruined print.

Frayed edges typically occur in cold laminated flex banners due to dull cutting blades during slitting, causing polyester fibers to protrude. This issue is absent in hot laminated banners because heat fuses the edges. Preventing it requires sharp blades and strict machine maintenance to protect expensive printer heads.

As a technophile deeply involved in manufacturing coated textiles at Hangzhou Nuclear Coated Fabrics Co., Ltd., I know that precision begins long before the ink hits the substrate. Frayed edges in flex banners, particularly in cold laminated types, are more than a cosmetic flaw; they represent a significant risk. The primary cause is often the slitting process where wide base fabrics, frequently 3.2 meters, are cut into smaller widths. If the blades are worn or not sharp enough, the polyester base fabric's fibers become loose, creating what we call "Frayed edges" 1. Hot lamination processes avoid this because the heat seals the fibers, but cold lamination offers no such inherent protection. I've often seen these stray fibers scratch delicate and expensive printer heads2, such as those from Konica, Epson, Fuji, HP, and Roland. This can lead to costly repairs and downtime.

To address this, two immediate techniques are effective. First, using an alcohol lamp to gently melt the edges can fuse the individual fibers, essentially stopping the fraying. However, this method carries an obvious fire risk and requires careful handling. Second, a hot knife, or hot wedge, can be used to melt and seal the edge in a more controlled manner, though it still demands caution to prevent burns. My long-term solution focuses on prevention at the source: implementing stringent maintenance protocols for cutting machinery and ensuring blades are always sharp. This proactive approach minimizes risk and maximizes efficiency, reflecting Mr. Watford's principle of managing risk by finding reliable partners.

| Problem Aspect | Cause | Immediate Solution | Long-term Prevention | My Operational Insight |

|---|---|---|---|---|

| Fiber Protrusion 1 | Dull slitting blades 3 | Alcohol lamp / Hot knife heat sealing | Regular blade sharpening & maintenance | Critical for preventing damage to sensitive printing heads, a common frustration for users with high-end equipment. |

| Increased Risk for Cold Lamination | Lack of heat sealing in process | Careful application of heat post-production | N/A (inherent process limitation) | Explaining this distinction helps manage customer expectations and guides them towards appropriate material choices. |

| Printer Head Damage 2 | Loose fibers scraping nozzles | Immediate edge treatment | Proactive quality checks post-slitting | Protecting valuable assets like printer heads is paramount; it's about minimizing hidden costs and maximizing uptime. |

| Labor & Time Cost | Manual edge finishing (post-production) | Streamlined heat sealing tools | Optimized cutting processes | Extra steps mean extra costs. Investing in good manufacturing practices outweighs constant damage control. |

Does Your Flex Banner Feel Sticky, Especially in Warm Climates?

Are you experiencing frustratingly sticky flex banner surfaces, particularly after storage or in warm weather? This common problem, often leading to customer complaints, has a clear chemical cause.

Flex banner stickiness, most noticeable in heat or after humid storage, happens when plasticizers migrate from the PVC core to the surface. It can be temporarily fixed with alcohol wipes. The best prevention involves optimal storage at 22-25°C and 50-55% humidity, and recommending semi-gloss or matte finishes for high-risk environments.

The phenomenon of a sticky flex banner surface is something I've seen customers struggle with, particularly those in warmer climates like the Middle East and Africa. It's often reported after products have been produced in hot weather, transported in containers across oceans in varying temperatures, or stored in humid, warm warehouses. The root cause is chemical: plasticizers4 within the PVC film, which are essential for making the material flexible, become unstable under heat. They then migrate, or "bleed," from the internal PVC layers to the surface of the banner, creating that unpleasant tacky feel. This issue is a fundamental material science challenge that deeply fascinates me, as a true technophile always exploring material science. My team ensures our coated technical textiles meet stringent global demands, including stability in various climates.

To offer immediate relief, a 70%-90% concentration of isopropyl alcohol (IPA)5 or ethanol6 can be used to wipe down the surface. Stronger stickiness usually requires higher alcohol concentrations. However, this is a temporary fix. For long-term prevention, optimizing storage conditions is paramount. I always advise partners to store flex banners in environments with temperatures between 22-25°C and a relative humidity of 50-55%. This range minimizes plasticizer4 migration. Another key strategy is to recommend alternative surface finishes. While high-gloss surfaces offer immediate visual appeal, they are the most susceptible to stickiness. Suggesting semi-gloss or matte finishes, especially for projects destined for hot regions or extended storage, can significantly mitigate this risk. Before any large production run, I always tell my team and partners to conduct small-sample tests to verify the surface condition and prevent large-scale losses, aligning with Mr. Watford's value of evaluating media.

| Problem Aspect | Cause | Immediate Solution (Temporary) | Long-term Prevention & Best Practice | My Customer-Focused Approach |

|---|---|---|---|---|

| Tacky Surface | Plasticizer migration from PVC due to heat/humidity 7 | Wipe with 70-90% alcohol (IPA/ethanol) | Optimize storage: 22-25°C, 50-55% RH | Proactively educating clients on ideal storage and the benefits of different finishes (semi-gloss/matte) builds trust and manages expectations, especially in challenging climates. |

| Increased Risk (High Gloss) | High gloss finishes have higher migration risk | N/A | Recommend semi-gloss/matte for high-risk use | Understanding the nuances of material composition allows me to offer tailored advice and solutions that genuinely help clients solve their problems before they arise. |

| Seasonal/Geographical Impact | Hot seasons, container shipping, hot climates | Expedited use/cooling | Pre-testing small samples before bulk print | This issue underscores the importance of regional market knowledge. What works in one climate might fail in another, hence the need for adaptable supply chains and product development tailored to geographical demands. |

| Material Degradation 8 | Prolonged exposure to poor conditions | N/A | Quality control and material science research | Continual research into material science helps us develop more stable formulations, a core principle at Hangzhou Nuclear Coated Fabrics Co., Ltd. |

Are Your Flex Banner Prints Lacking Vibrant, Eye-Catching Colors?

Are your flex banner prints consistently coming out dull, or lacking the vibrant punch you expect, failing to capture attention? This common printing frustration often stems from overlooked technical details.

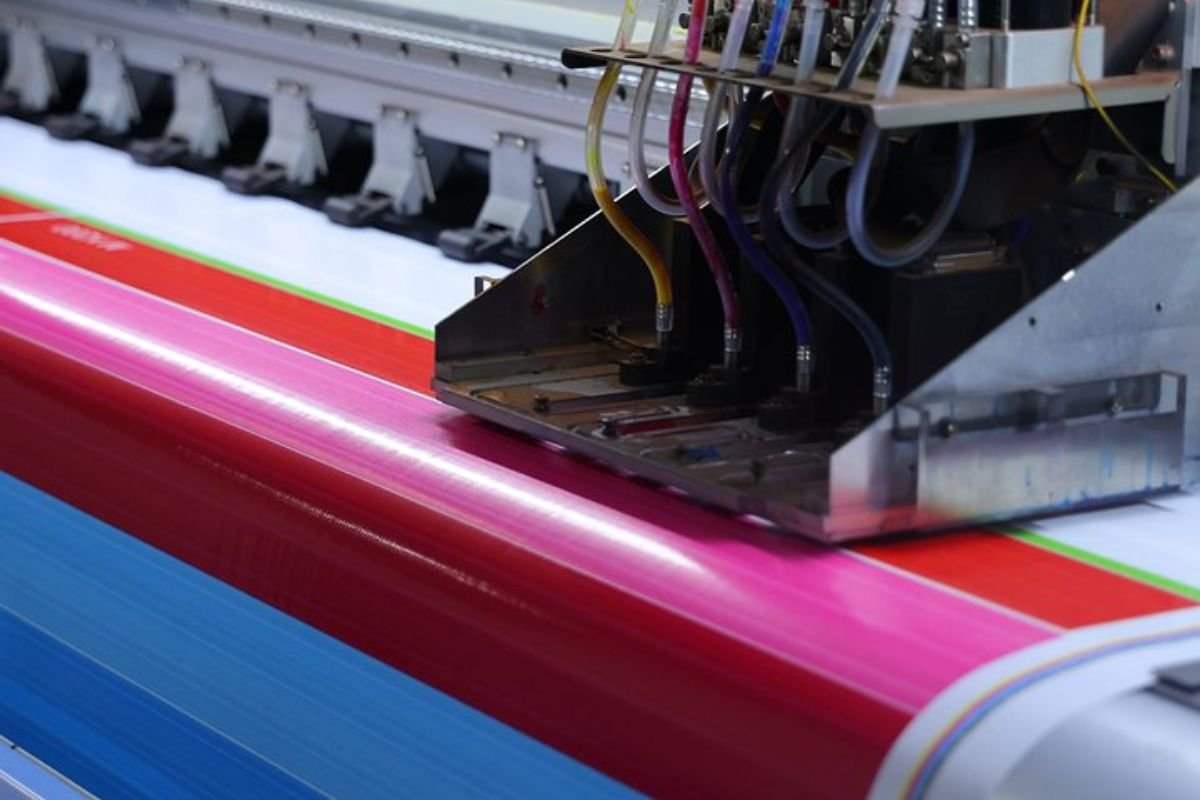

Dull flex banner colors often result from a mismatch between the material, ink, and printer, or incorrect ICC profiles. A quick fix is increasing ink output, though costly. The best solution is professional color calibration with specialized tools like X-Rite EyeOne, generating custom ICC curves for optimal, cost-effective vibrancy.

Achieving vibrant, true-to-life colors on flex banners is an art and a science, a challenge I've tackled countless times, both in my manufacturing role and when helping clients. The moment a client tells me their blacks look gray or their reds appear orange, I know we are dealing with a classic case of color mismatch. The core problem lies in the intricate interplay between the material itself, the printing ink used, and the specific printing equipment. It’s a "race between material, ink, and print device," as I often tell my partners. Equipment manufacturers aim for versatility, material suppliers strive for compatibility, but the end-user needs to find that sweet spot for optimal color reproduction. Often, the default ICC profile9 (International Color Consortium profile) or ink output settings simply aren't optimized for a particular flex banner material, leading to flat, uninspired results.

There are two primary paths to more vivid colors. The quickest, though not the most economical, is to simply increase the ink output. For example, boosting it from 100% to 200% will immediately add saturation. However, this dramatically escalates ink costs, impacting profitability. A more professional and sustainable solution involves using specialized color calibration equipment, such as an X-Rite EyeOne10, ColorMunki Display11, or Datacolor Spyder Print12. These tools help create a custom ICC profile specifically for your printer, ink, and flex banner combination. This method ensures accurate color rendition while optimizing ink consumption, making it the most cost-effective long-term strategy for achieving brilliant colors. While it requires a skilled technician, it’s an investment that pays off, embodying Mr. Watford's preference for a solutions-oriented approach to overcome unique project challenges.

| Problem Aspect | Cause | Quick Solution (Costly) | Professional Solution (Optimal) | My Technical Guidance |

|---|---|---|---|---|

| Dull/Flat Colors | Mismatch: material, ink, printer, or generic ICC profile 9 | Increase ink output (e.g., 100% to 200%) | Generate custom ICC profile with calibration tools 13 | This is often where a deeper technical dive is needed. I always advise partners to invest in understanding color management; it's a game-changer for print quality and efficiency, aligning with a focus on cutting-edge solutions. |

| Suboptimal Color Saturation | Inefficient use of ink for specific material | Higher ink consumption | Optimized ink usage (custom profiles) | The "race" analogy highlights the need for a holistic view. You can't blame one component; you must optimize the system as a whole. My role is to help clients achieve this balance. |

| Inaccurate Color Reproduction | Default settings not suited to material's absorption | N/A | Accurate color matching and consistency | For a professional like Mr. Watford, color consistency is non-negotiable. Custom ICC profiles ensure that colors are reproduced accurately every time, crucial for brand integrity across various projects. |

| High Ink Costs | Over-inking to compensate for dullness | Immediate, but costly | Long-term savings through efficiency | While throwing more ink at the problem offers a quick visual fix, it's financially unsustainable. I emphasize long-term, data-driven solutions that protect profitability. |

Why Does My Flex Banner Feel Too Soft, Suggesting Under-Weight?

Are clients sometimes reporting that your flex banner materials feel too soft, creating the impression of being lightweight or "under spec?" This common perception often disguises a different material characteristic.

A flex banner feeling soft often leads to a misconception of insufficient weight, especially in hot regions. This "softness" is primarily determined by the phr value, which indicates plasticizer content. Higher phr makes the material softer, while lowering it, for example to 38 phr from a standard 42 phr, results in a firmer feel.

The perception of a flex banner feeling "too soft" is an issue I frequently encounter, especially with clients in hot climates like the Middle East and Africa. It's often misinterpreted as the material being insufficient in weight. However, the reality points to a specific chemical property: the phr value14, which stands for "parts per hundred parts of resin." This value directly quantifies the amount of plasticizer in the PVC compound. As a technophile who thrives on understanding material science, I know that a higher phr value means more plasticizers are added, resulting in a softer, more pliable material. Conversely, a lower phr value produces a stiffer, firmer banner. A standard formulation typically hovers around 42 phr. If a client expresses a preference for a more rigid feel, we can adjust the phr value down to around 38 phr during manufacturing.

My approach to this involves proactive communication with partners. It's not just about producing a product; it’s about educating the client on the technical specifications and managing their expectations. By thoroughly explaining what phr means and how it impacts the material's feel, we can avoid misunderstandings and build trust. This kind of transparent, solutions-oriented partnership is precisely what Mr. Watford seeks. It also reflects my commitment to empowering partners through knowledge-sharing, ensuring they understand the "why" behind material characteristics and can make informed choices based on their target market's preferences. It's about providing the right solution, not just any solution.

| Problem Aspect | Cause | Solution (Proactive) | Client Communication Strategy | My Approach to Partnership |

|---|---|---|---|---|

| "Soft" Feel Perception | High phr value (plasticizer content) 14 | Adjust phr value pre-production | Transparently explain phr and its impact | Guiding clients to understand the science behind material feel helps them make informed decisions and reduces misinterpretations, building a stronger supplier-client relationship. |

| Customer Misconception | Equating softness with low weight | N/A | Educate on material science versus subjective feel | This is where technical knowledge becomes client solutions. Empowering partners with information helps them serve their own markets better. |

| Regional Preference (Hot Climates) | Materials soften more in heat, exacerbating issues | Offer customized phr options | Tailored recommendations based on market needs | My global business experience, especially with clients like Manish Aggarwal, taught me the importance of adapting product characteristics to regional demands and preferences. |

| Material Performance | Impact on handling and installation | Lower phr for desired stiffness | Set clear expectations on material properties | The goal is to provide materials that perform optimally for the specific application and environment, not just to sell a product. This demonstrates a solutions-oriented approach. |

Is Your Flex Banner Material's Weight Inconsistent or Under-Spec?

Are you concerned about discrepancies in your flex banner material's weight, suspecting it might be inconsistent or less than advertised? Verifying the actual linear weight requires precise measurement.

Inconsistent flex banner weight can stem from production variances (thicker edges, thinner middle) or deliberate mislabeling. To ensure accuracy, measure multiple samples across the width and average the grammage. The most reliable method is to weigh the entire roll and then subtract the core's weight, allowing for calculation of true average grammage.

The issue of perceived insufficient weight in flex banner materials is a sensitive one, and validating it requires a methodical approach. From my manufacturing experience, I know that even in precise calendering processes, the film itself can exhibit slight thickness variations, typically being "thicker at the edges and thinner in the middle." If a customer happens to measure only the thinner central portion, they might mistakenly conclude the overall weight is lower than specified. Sadly, there are also instances where some suppliers deliberately provide lower-grammage products (e.g., a 500D product15 labeled 440gsm actually being 350-380gsm for the Mexican market) to meet extremely competitive price points. This practice I do not condone, as it undermines trust and quality.

To ensure accuracy and fairness for both buyer and seller, I advocate for strict quality control measures. First, for wide-format materials (e.g., 3.2 meters wide), it is crucial to collect at least 10 samples evenly across the width and calculate the average grammage16 (gsm). This prevents anomalies from isolated measurements. However, the most reliable method for verifying average grammage is to weigh the entire roll at the factory gate. The net weight of the material can be accurately derived by subtracting the weight of the paper core. For example, for a 3.2-meter wide roll, the paper core length is usually around 3.25 meters. If a standard 0.7mm thick paper core weighs approximately 1.1 kg/meter, the total core weight would be 3.25 m × 1.1 kg/m ≈ 3.575 kg. Subtracting this from the gross roll weight provides the material's net weight, from which the average grammage can be accurately calculated. This rigorous process helps distinguish between slight production variation and deliberate misrepresentation, building the kind of transparent, trustworthy partnership Mr. Watford values in his supply chain, which he likens to a precision-engineered printer.

| Problem Aspect | Cause | Solution (Measurement Protocol) | Quality Control Best Practice | My Commitment to Transparency |

|---|---|---|---|---|

| Perceived Low Weight | Production thickness variation ("edges thick, middle thin"); selective localized sampling 17 | Measure 10 samples across width & average | Full roll weight verification (net weight calculation) | I actively provide this measurement guidance to help clients accurately assess products, differentiating between natural production variation and deliberate quality issues. This builds trust and ensures fairness for all. |

| Deliberate Mislabeling | Price competition, unethical practices | N/A (requires ethical sourcing) | Partner with trusted, audited suppliers | As the founder of nlsigns.com and Hangzhou Nuclear Coated Fabrics Co., Ltd., I believe in ethical manufacturing. Explicitly stating this method combats market deception and protects my clients' interests. |

| Measurement Inconsistency | Single-point measurement error | Standardized multi-point sampling | Training on proper measurement techniques | Ensuring clients understand and apply proper measurement protocols is an extension of my knowledge-sharing philosophy, empowering them to verify product specifications effectively. |

| Risk to Buyer | Paying for advertised weight, receiving less | Transparent verification methods | Open communication and robust contracts | My partnerships, like the one with Manish Aggarwal, are built on trust and transparent dealings. This detailed approach to weight verification safeguards our mutual interests. |

Addressing common flex banner material problems demands a blend of technical understanding, proactive solutions, and transparent communication. By focusing on root causes like frayed edges, surface stickiness, dull colors, and weight discrepancies, we can ensure consistent quality, protect equipment, and build stronger, more reliable partnerships for mutual growth and success.

Further readings

Frayed Edges: Understanding fiber fraying in textiles. See Wikipedia, "Textile fiber" 18 7. ↩ ↩

Printer Head: For detailed information on print head technology. See Wikipedia, "Print head" 19 8. ↩ ↩

Slitting (manufacturing): Learn about the industrial process of slitting. See Wikipedia, "Slitting (manufacturing)" 20 9. ↩

Plasticizer: A substance added to a material to make it softer and more flexible. See Wikipedia, "Plasticizer" 21 10. ↩ ↩

Isopropyl Alcohol (IPA): Chemical properties and uses. See Wikipedia, "Isopropyl alcohol" 22 11. ↩

Ethanol: Chemical properties and uses. See Wikipedia, "Ethanol" 23 12. ↩

Plasticizer Migration: How plasticizers move within a material. See Wikipedia, "Material degradation" 24 13. ↩

Material Degradation: Understanding the process of material breakdown. See Wikipedia, "Material degradation" 25 14. ↩

ICC Profile: A set of data that characterizes a color input or output device. See Wikipedia, "ICC profile" 26 15. ↩ ↩

X-Rite EyeOne (i1): A popular series of spectrophotometers for color calibration. See official X-Rite website 27 16. ↩

ColorMunki Display: A colorimeter for display calibration. See official X-Rite website 28 17. ↩

Datacolor Spyder Print: A device for printer profiling. See official Datacolor website 29 18. ↩

Color Management: The controlled conversion between the color capabilities of various devices. See Wikipedia, "Color management" 30 19. ↩

Phr (parts per hundred resin): A common metric in polymer chemistry. See Wikipedia, "Polymer chemistry" 31 20 or search for "phr plasticizer definition" from chemical industry sources. ↩ ↩

Denier (D): A unit of linear mass density of fibers. See Wikipedia, "Denier (unit)" 32 21. ↩

Grammage (gsm): Mass per unit area of a material. See Wikipedia, "Grammage" 33 22. ↩

Calendering Process: A finishing process used to smooth and compress a material. See Wikipedia, "Calender (paper)" 34 23 for similar principles in manufacturing. ↩