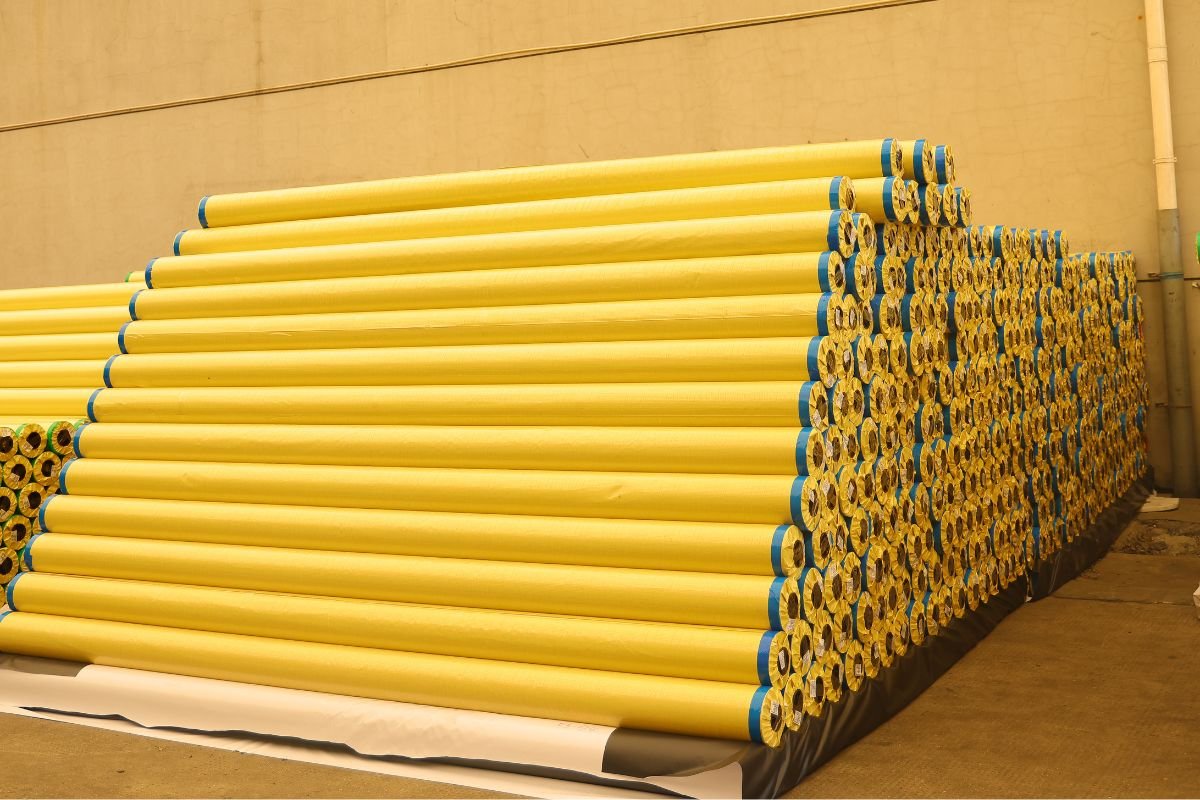

Have you ever stopped to think about what those large, colorful advertisements or informational signs are made of? They are everywhere, from storefronts to sports events. The secret lies in something called banner material.

Banner material is a general term for the various flexible substrates used for printing visual advertisements, displays, and informational signs. It is specifically engineered to be printable, durable, and often weather-resistant, making it suitable for a wide range of indoor and outdoor applications.

From my very first days working in a signage media factory, the variety of materials was astounding. Beyond just knowing what a "banner" was, I had to understand what it was made of. This was crucial because each material has its own strengths and is suited for different uses. It's not just about printing a picture; it's about making sure that picture lasts, looks good, and serves its purpose in the right environment. My work at nlsigns.com often involves advising clients on the best material for their flex banner production. This requires a deep understanding of these fundamental components.

What is Banner Material Made Of?

Understanding the composition is key to choosing the right banner for the job. It's more complex than just "plastic."

Banner material is primarily made from a combination of synthetic polymers, most commonly PVC (polyvinyl chloride)[^1], often reinforced with a fabric scrim[^2] (typically polyester)[^3]. Additional coatings or laminations[^4] are applied to enhance printability, durability, and weather resistance.

When I first learned about banner material composition, I imagined a simple sheet. But it's much more structured. The polyester scrim is like the backbone. It gives the banner its strength and keeps it from tearing easily. Then, the PVC layers are applied around this scrim. This PVC provides the smooth, printable surface and makes the banner resistant to water and many outdoor elements. There are different ways to apply this PVC: either through coating, where liquid PVC is applied to the scrim, or lamination, where PVC films are glued onto the scrim. Each method produces material with slightly different properties.

Components of Banner Material

| Component | Description | Function | Common Variations |

|---|---|---|---|

| PVC (Polyvinyl Chloride) | Synthetic plastic polymer. | Provides smooth printable surface, water resistance, flexibility. | Different formulations for various flexibilities and durabilities. |

| Polyester Scrim | Woven polyester fabric mesh. | Reinforcement layer, provides tear strength and dimensional stability. | Different deniers (e.g., 300D, 500D, 1000D) and weave patterns. |

| Coatings/Laminations | Outer layers of PVC or other polymers. | Enhances ink adhesion, weather resistance, UV protection, gloss/matte finish. | Frontlit, backlit, blockout coatings; gloss or matte finish. |

| Additives | Various chemicals (e.g., plasticizers, UV stabilizers). | Improves flexibility, fire resistance, UV resistance, lifespan. | Anti-UV agents, flame retardants, anti-Fungus agents. |

What is Scrim Banner Material?

The term "scrim" comes up often in our conversations. It refers to a critical part of the banner.

Scrim banner material refers to banner media that incorporates an internal woven polyester mesh, known as a scrim. This scrim is embedded within layers of PVC to provide enhanced tear strength, dimensional stability, and overall durability. It is the core reinforcement that allows banners to withstand tension and outdoor elements.

I've always taught our teams that the scrim is the hidden hero of the banner. If you hold a piece of scrim banner material up to the light (before it's fully coated), you can often see the grid pattern of the woven fibers. This internal structure is what prevents a small tear from ripping across the entire banner in the wind. When a client like Mr. Watford, with his 15 years of experience, discusses banner quality, the scrim plays a big role. A higher denier[^5] count or a tighter weave in the scrim means a stronger, more resilient banner. This attention to detail is why our products meet stringent demands for durability.

Characteristics of Scrim Banner Material

| Feature | Description | Benefit | Impact on Quality |

|---|---|---|---|

| Internal Scrim | Woven polyester mesh embedded in PVC layers. | Provides exceptional tear resistance and stability. | Prevents stretching, fraying, and catastrophic tearing. |

| Strength | Significantly stronger than unsupported vinyl films. | Withstands wind, tension from hanging, and handling. | Longer lifespan for outdoor applications. |

| Durability | Enhanced resistance to outdoor elements and stress. | Ideal for long-term outdoor signage and billboards. | Reliable performance in various weather conditions. |

| Weight | Generally heavier and thicker than non-scrim materials. | Indicates robust construction for demanding uses. | Better drape, less prone to wrinkling. |

What is Vinyl Banner Material?

This is perhaps the most common term our clients use. It's often used broadly, but it has specific meaning.

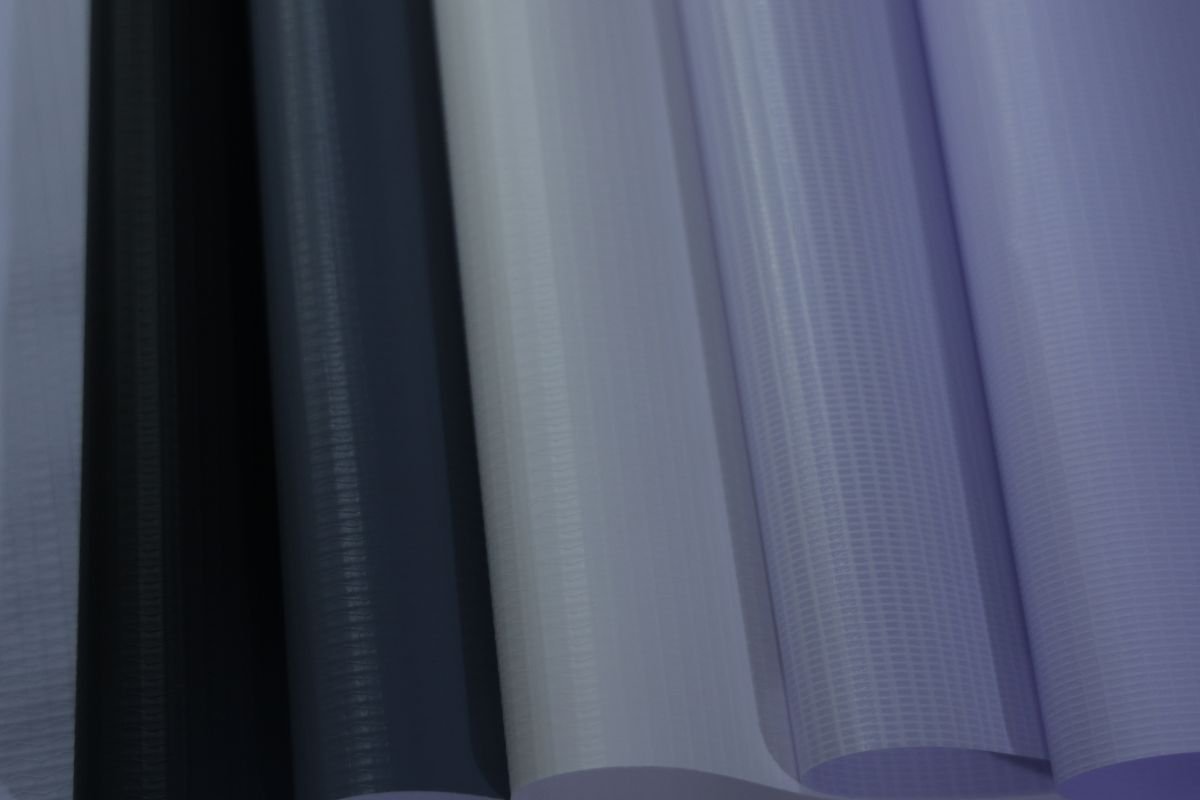

Vinyl banner material typically refers to any banner substrate primarily composed of PVC (polyvinyl chloride)[^1]. It is characterized by its smooth, flexible, and printable surface, making it the most popular choice for a wide range of advertising and display purposes due to its versatility, affordability, and weather resistance.

When someone says "vinyl banner," for me, it immediately brings to mind the workhorse of the advertising world. It's the go-to material for most flex banner needs. My company focuses on high-quality printable media, and vinyl is at the heart of that. It's adaptable; it can be made for frontlit[^6] or backlit[^7] applications, and it can be designed to block out light for double-sided printing. The consistency in quality of vinyl banner material is crucial. From my experience managing a manufacturing operation, ensuring that each roll delivers vibrant color reproduction and consistent quality is paramount, and it all starts with the properties of the vinyl itself.

Types and Characteristics of Vinyl Banner Material

| Characteristic | Description | Common Variations | Typical Applications |

|---|---|---|---|

| Composition | Primarily PVC, often with a polyester scrim reinforcement. | Coated vs. Laminated; different PVC formulations. | Wide range of indoor and outdoor signs. |

| Surface Finish | Smooth and flexible. | Matte, gloss, and satin finishes for different looks. | Billboards, trade show graphics, event banners. |

| Printability | Excellent ink adhesion for various printing technologies. | Optimized for UV[^8], solvent[^9], eco-solvent[^10], and latex[^11] inks. | Any digitally printed graphic display. |

| Durability | Weather-resistant, tear-resistant (especially with scrim). | Longevity varies based on material quality and application (indoor vs. outdoor). | Long-term outdoor advertising, short-term promotions. |

| Opacity | Varies from translucent to opaque. | Frontlit (opaque), Backlit (translucent), Blockout (opaque for double-sided). | Specific uses like illuminated signs or two-sided banners. |

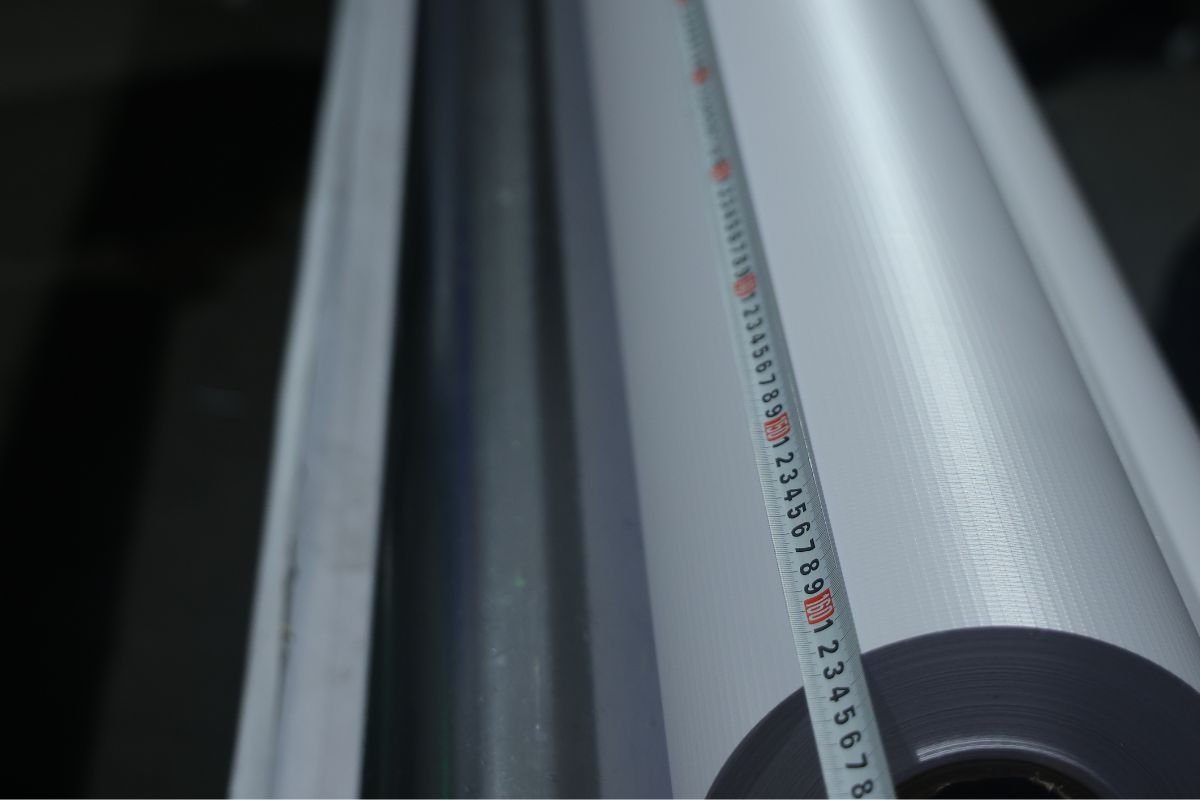

How is Banner Material Gauged?

Understanding how banner material is measured helps in choosing the right product for specific needs.

Banner material is primarily gauged by its weight per unit area, typically expressed in grams per square meter (GSM)[^12] or ounces per square yard (oz/yd²). This measurement indicates the material's thickness and density, with higher GSM ratings generally correlating to increased durability and robustness. Other factors like denier and thread count of the scrim also contribute to gauging quality.

For me, GSM is one of the first numbers I consider when evaluating a banner material. It tells me a lot about its strength and intended use. A lighter GSM banner, say 280 GSM, might be good for a temporary indoor sign. But for an outdoor billboard, you'd likely need something much heavier, perhaps 440 GSM or even 610 GSM. The GSM often correlates closely with the denier of the internal scrim and the thickness of the PVC coating. These measurements give us a standardized way to compare and specify materials. Mr. Watford, our experienced purchasing professional, would definitely look at these numbers to ensure he's getting the right product for the job's demands.

Key Metrics for Gauging Banner Material

| Metric | Description | Significance | Example Values (for common flex banners) |

|---|---|---|---|

| GSM (Grams per Square Meter) | Weight of the material per square meter. | Indicates thickness, density, and overall robustness. | Light (280-340 GSM), Medium (380-440 GSM), Heavy (510-610 GSM+). |

| Oz/Yd² (Ounce per Square Yard) | Equivalent weight measurement in imperial units. | Alternative unit, commonly used in North America. | 9 oz/yd² to 20 oz/yd² and above. |

| Denier | Unit of measurement for the linear mass density of fibers (for scrim). | Indicates the thickness and strength of individual scrim threads. | 200D, 300D, 500D, 1000D. Higher is stronger. |

| Thread Count | Number of threads per inch in the scrim (e.g., 20x20, 42x40). | Indicates the weave density and overall strength of the scrim. | 20x20, 42x40. Higher density provides more strength. |

| Tensile Strength | Material's resistance to breaking under tension. | Important for banners under stress (e.g., wind load). | Measured in lbs/in or N/5cm. |

How to Weld Banner Material?

After printing, many banners need to be joined or finished. Welding is a key process for durability.

Banner material is commonly welded using heat or high-frequency (HF) welding techniques to create strong, durable seams or hems. This process involves melting the PVC material along the edges, then pressing them together to form a permanent bond, essential for creating large banners or reinforcing edges for grommets[^13].

Welding banners is a critical step in finishing. I've seen firsthand how a well-welded seam stands up to years of outdoor exposure versus a poorly bonded one. For large banners, like those for building facades, you can't just print one giant piece. You print several sections and then weld them together seamlessly. This requires precision. Heat welding machines use hot air to melt the PVC, creating a very strong, waterproof bond. HF welding, on the other hand, uses radio frequency energy to heat and fuse the material. Both methods create incredibly strong seams that often make the welded area as strong as, or even stronger than, the original material. This detail ensures the final product is not only vibrant but also robust.

Common Methods for Welding Banner Material

| Method | Description | Key Advantages | Typical Applications |

|---|---|---|---|

| Heat Welding (Hot Air) | Uses hot air to melt the thermoplastic material, followed by pressure. | Strong, waterproof, versatile for various PVC materials. | Hems, seams for large banners, pole pockets. |

| High-Frequency (HF) Welding | Uses radio frequency energy to generate heat and fuse materials. | Extremely strong, clean seams, suitable for thick materials. | Large-scale outdoor banners, industrial covers. |

| Impulse Welding | Uses a heated element for a short burst of heat and pressure. | Good for quick seals, can be used for thinner materials. | Hems, quick seals on smaller banners. |

| Solvent Welding (Chemical) | Uses a chemical solvent to temporarily dissolve and fuse surfaces. | Simple, effective for small repairs or specific materials. | Repairing tears, specific light-duty applications. |

Conclusion

Banner material, usually PVC reinforced with scrim, forms the basis of countless ads. It is gauged by weight (GSM) and welded using heat or HF methods for durability. Understanding its composition and processing ensures effective, long-lasting visual communication.

Annotated Reading:

- PVC (Polyvinyl Chloride): A widely produced synthetic plastic polymer known for its versatility. It is used in construction, healthcare, electronics, and especially in the signage industry for banners and films due to its durability and water resistance. https://en.wikipedia.org/wiki/Polyvinyl_chloride

- Scrim: The internal woven mesh fabric, typically made from polyester or nylon, embedded within PVC layers of a banner to provide added tear strength and dimensional stability.

- Polyester: A synthetic polymer widely used in textiles, including the reinforcement scrim in banners, known for its strength, durability, and resistance to shrinking and stretching. https://en.wikipedia.org/wiki/Polyester

- Lamination: A process where multiple layers of material (e.g., PVC film, scrim, PVC film) are bonded together, often using heat and pressure, to create a composite material like laminated banner.

- Denier: A unit of measurement used to describe the linear mass density of fibers, particularly for the threads in the scrim layer. A higher denier number indicates a thicker, and generally stronger, thread.

- Frontlit Banner: A type of banner material designed to be illuminated from the front, suitable for general outdoor and indoor signage where the light source is external and positioned in front of the banner. It typically uses opaque materials.

- Backlit Banner: A type of banner material designed to be illuminated from behind, allowing the printed graphic to glow for high visibility, especially at night. It uses translucent materials.

- UV Printing: A type of digital printing that uses ultra-violet (UV) lights to cure or dry ink as it is printed. The liquid ink instantly turns into a solid, allowing printing on a wide range of materials and providing durable, vibrant results. https://en.wikipedia.org/wiki/UV_curable_ink

- Solvent Ink (Printing): A type of ink for wide-format printing where a solvent is used to carry the pigment. The solvent evaporates after printing, leaving the pigment on the surface. Known for durability and outdoor use. https://en.wikipedia.org/wiki/Solvent_ink

- Eco-Solvent Ink: A type of solvent ink that is less aggressive and contains fewer volatile organic compounds (VOCs) than traditional solvent inks, making them more environmentally friendly and suitable for indoor applications.

- Latex Ink (Printing): Water-based inks that contain polymer particles (latex) that are fused to the print medium using heat from the printer. They are environmentally friendly, durable, and suitable for both indoor and outdoor applications. https://en.wikipedia.org/wiki/Latex_ink

- GSM (Grams per Square Meter): A unit of measurement that indicates the surface density or weight of a material. In banners, a higher GSM generally means a thicker and more durable material.

- Grommets: Metal rings or eyelets inserted into holes along the edges of banners, used for hanging or securing the banner with ropes, bungee cords, or zip ties. https://en.wikipedia.org/wiki/Grommet