Are you looking for vibrant, long-lasting materials to create eye-catching signs, decals, or graphics? Professional buyers like Mr. Watford often seek specific details regarding Color Cutting Vinyl, also known as sign vinyl or plotter vinyl, which is a staple in the signage industry.

Color Cutting Vinyl is a specialized self-adhesive film that comes in a vast array of solid colors, designed to be cut into shapes, letters, and designs using a vinyl cutter or plotter. Unlike printable vinyl, this material is pre-colored and doesn't require printing; its color runs consistently through the film, making it ideal for durable, single-color graphics. The standard configurations often include various film thicknesses and release liner weights, such as 80-micron film with a 120gsm or 140gsm release liner, or 100-micron film with a 120gsm release liner.

From my early career days at Shanghai Chungkong Ad-Mart Co., Ltd., I witnessed firsthand the versatility and importance of Color Cutting Vinyl. It was a go-to material for creating everything from storefront lettering to promotional decals. This product, with its simplicity and effectiveness, always caught my eye because it delivers immediate, vivid results that are hard to miss.

What are the standard configurations and available color options?

Are you unsure about the typical thicknesses, release liner weights, or the sheer variety of colors available for Color Cutting Vinyl? Many of my partners, and indeed Mr. Watford, need precise specifications to match their project requirements and aesthetic goals.

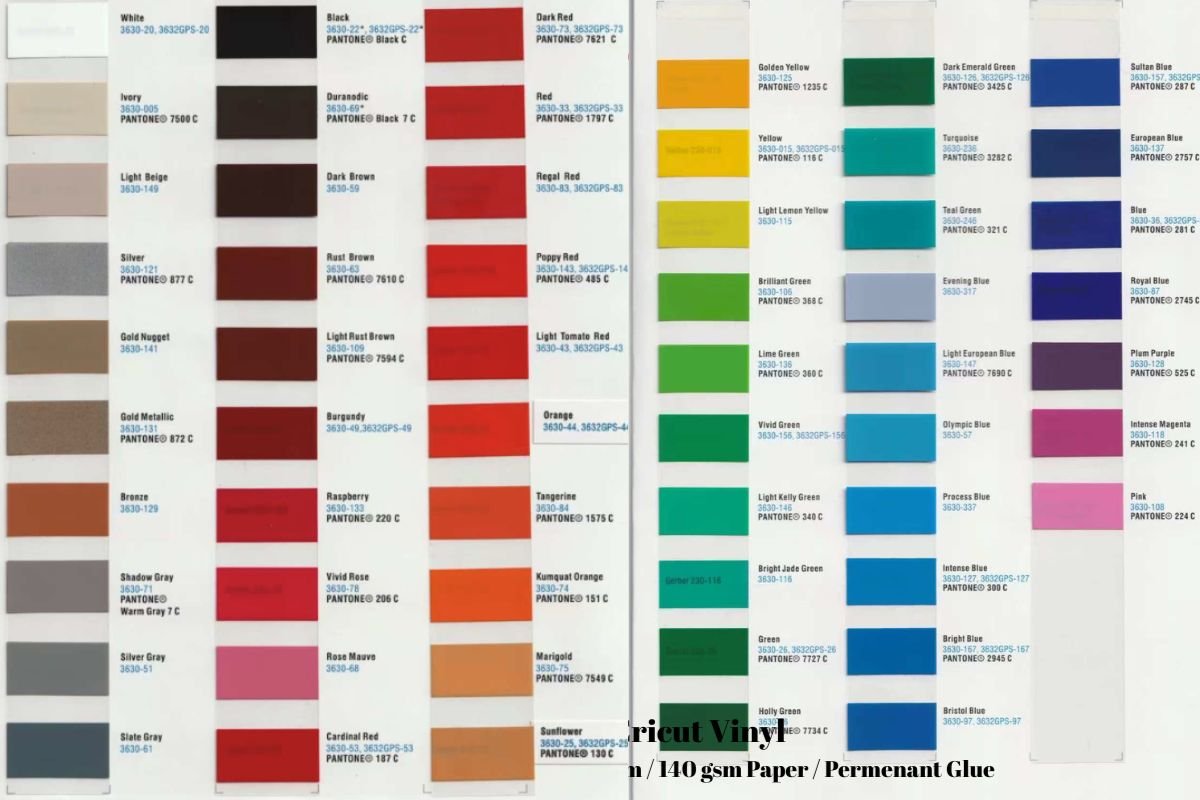

Color Cutting Vinyl typically comes in various standard configurations. The most common film thicknesses are 80 microns1 and 100 microns, usually paired with release liners of 120gsm2 or 140gsm. There are over 50 standard colors to choose from, often available in both glossy and matte finishes. Beyond these standard options, specialty colors like fluorescent, reflective3, metallic gold and silver, and brushed gold and silver are also available. Metallic gold, silver, and brushed versions come in both PET4 and PVC5 material options.

When I started nlsigns.com and Hangzhou Nuclear Coated Fabrics Co., Ltd., offering a wide range of colors and material configurations was a top priority. My first international client, Manish Aggarwal, emphasized the need for diverse options to meet India's dynamic signage market. Understanding these specifics is key to empowering my partners with the right choices.

To provide a clear overview, I often refer to this table when discussing the fundamental options in Color Cutting Vinyl with my clients. It summarizes the core variations that are critical for selection.

| Characteristic | Common Specifications | My Insight on Application |

|---|---|---|

| Film Thickness | 80 micron, 100 micron | 80 micron is good for general use, especially for intricate cuts. 100 micron offers more durability and is easier to handle for larger graphics. |

| Release Liner | 120gsm, 140gsm | A heavier liner (140gsm) provides better flatness and stability during cutting and transport, especially beneficial for larger rolls or intricate designs. |

| Standard Colors | Over 50 options (glossy & matte) | Glossy colors are vibrant and reflective, good for high-impact signs. Matte colors offer a sophisticated, non-glare finish, ideal for interior designs or subtle branding. |

| Specialty Colors | Fluorescent, Reflective, Metallic Gold/Silver, Brushed Gold/Silver | Fluorescent colors are great for temporary, high-visibility needs. Reflective vinyl is essential for safety and nighttime visibility. Metallics offer a premium, textured look for high-end applications. |

| Material Types (Specialty) | PET (for metallics), PVC (for metallics and standards) | PET metallics often have a higher sheen and dimensional stability. PVC is more conformable and generally more cost-effective for standard colors. |

The choice depends a lot on the specific application's aesthetic and durability requirements.

What are the typical roll sizes and customization options for large-scale operations?

Are you finding that standard roll sizes for Color Cutting Vinyl don't quite fit your high-volume production needs? Many large advertising shops and my strategic partners often require larger rolls and customized options to optimize their workflow and reduce waste.

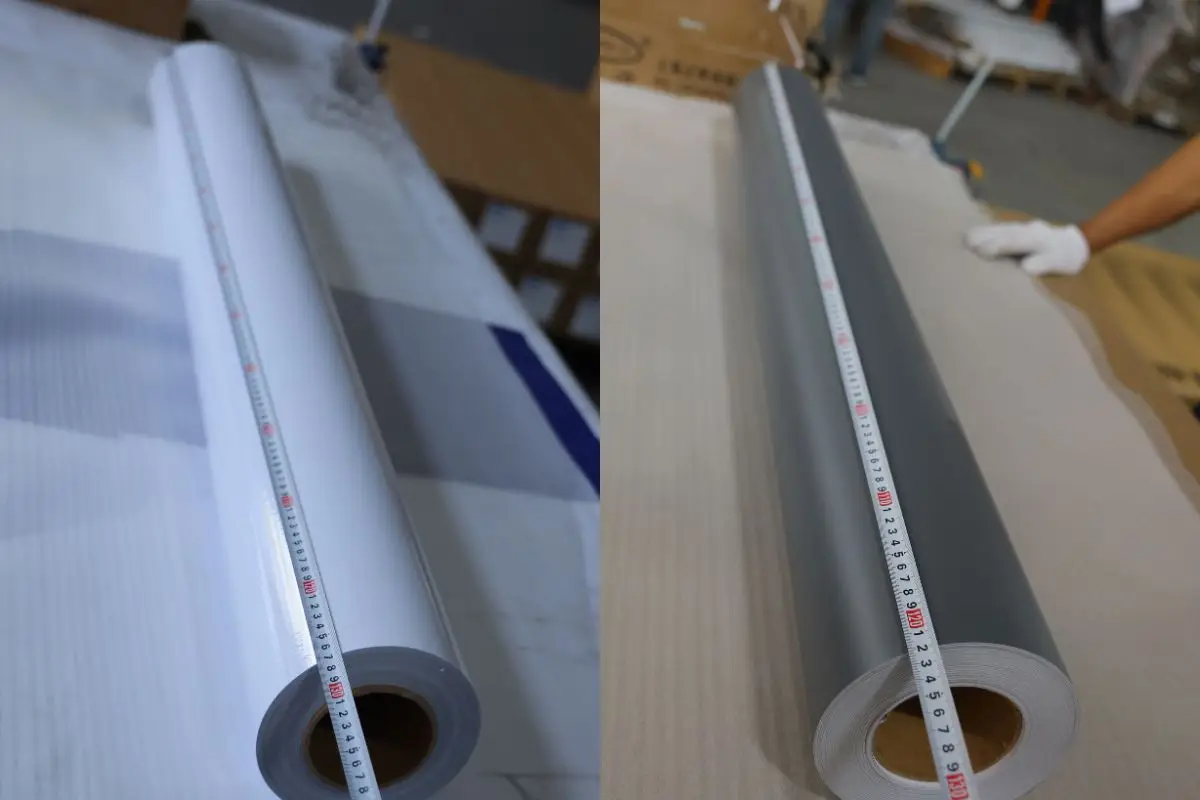

Standard Color Cutting Vinyl typically comes in rolls of 0.61m x 50m and 1.22m x 50m. However, for large advertising shops that process significant volumes of vinyl, customized roll lengths of 100m to 200m are often available. This helps reduce roll changes and improve operational efficiency. Furthermore, for companies seeking to strengthen their brand identity, customizing the release liner with a printed logo and using custom-colored cardboard packaging are viable options.

When I established Hangzhou Nuclear Coated Fabrics Co., Ltd., one of my core philosophies was to empower partners worldwide by providing comprehensive support, from raw materials to customized solutions. I understand that optimizing supply chains is critical for businesses like those Mr. Watford manages. Custom roll lengths and branded packaging are not just about aesthetics; they are about efficiency, brand consistency, and ultimately, cost savings for serious buyers.

Here's an overview of the typical roll sizes and available customization options, which can significantly benefit businesses with high-volume cutting operations.

| Feature | Standard/Common | Customization Options | My Advice for Buyers |

|---|---|---|---|

| Standard Roll Dimensions | 0.61m x 50m, 1.22m x 50m | N/A | These are widely available and suitable for most small to medium operations. |

| Length Customization | N/A | 100m, 200m rolls (for large volume) | If you process high volumes, customized longer rolls reduce downtime from changing rolls and can lead to better bulk pricing. Inquire about minimum order quantities. |

| Release Liner Branding | Plain release liner | Custom logo printing on the release liner | A branded liner reinforces your company's identity and professionalism, especially important if you supply materials to smaller shops or end-users. |

| Packaging Customization | Standard cardboard packaging | Custom-colored cardboard cartons, branded boxes | Custom packaging helps with inventory management and marketing. It can also differentiate your product in a competitive market. |

| Minimum Order Quantity (MOQ) | Generally lower for standard sizes/colors | Typically higher for customized lengths, branding, and packaging | Be prepared for higher MOQs on custom orders. These are often justified by the efficiency gains and branding benefits over time. Build long-term relationships to negotiate flexibility. |

This flexibility in sizing and branding helps large operations streamline their processes and enhance their market presence.

What film type (monomeric vs. polymeric) is ideal for outdoor longevity and shrinkage resistance?

Are you concerned about your outdoor vinyl graphics shrinking, cracking, or fading prematurely? Choosing the correct film type, either monomeric or polymeric, is crucial for ensuring the long-term performance and aesthetic integrity of your Color Cutting Vinyl applications.

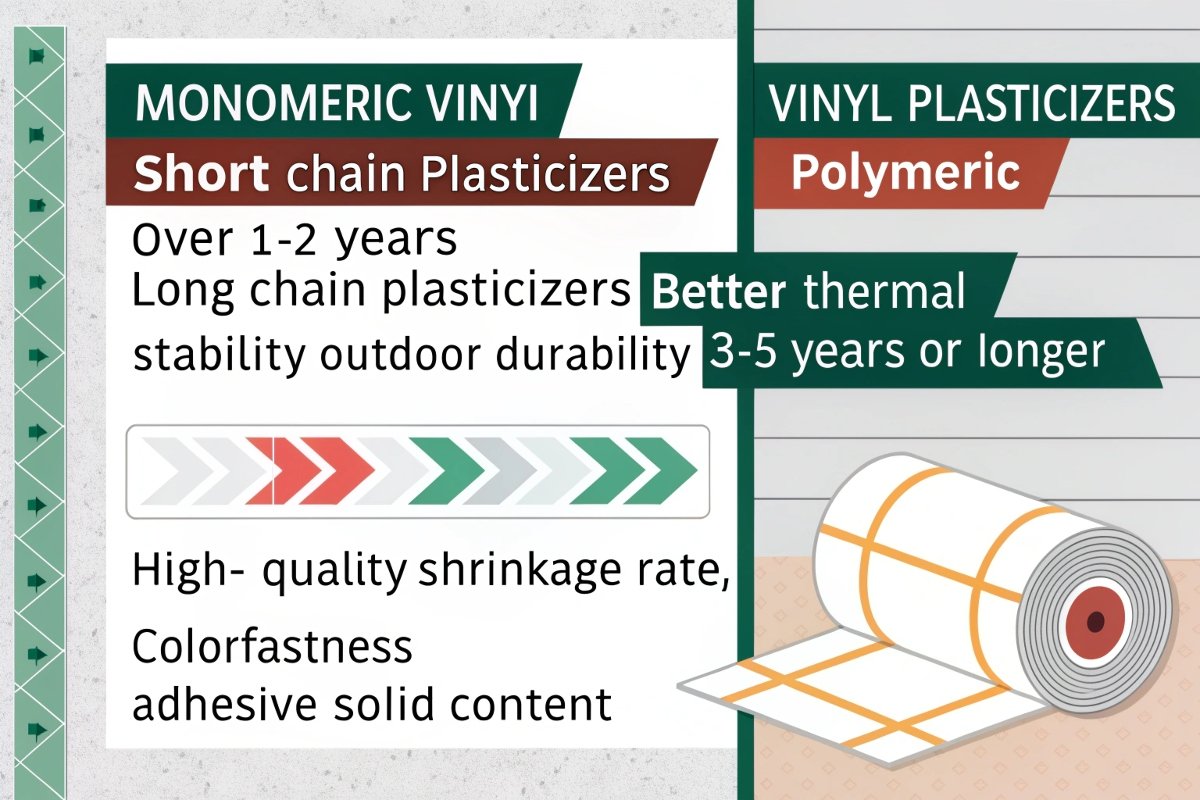

The key difference lies in the molecular structure of the plasticizers6 used in the vinyl film. Monomeric vinyl is made with short-chain plasticizers, making it more prone to shrinkage and degradation over time, limiting its outdoor life to 1-2 years. Polymeric vinyl, on the other hand, uses long-chain plasticizers, which lead to significantly better thermal stability7 and less shrinkage, extending its outdoor durability to 3-5 years or even longer. For applications requiring 3-5 years of outdoor use, the film's shrinkage rate, colorfastness8, and adhesive solid content all need to be of high quality.

In my nearly two decades in this industry, I have seen countless examples where choosing the wrong film type led to costly replacements and disappointed customers. Mr. Watford, with his detailed knowledge of print media durability from evaluating brands like 3M, understands that sacrificing quality at the start often leads to higher overall costs. This is why I always stress the importance of using polymeric materials for anything beyond very short-term outdoor use, especially for applications where visual consistency is critical.

Here’s a comparison that helps clarify the advantages of each film type for different outdoor applications.

| Feature | Monomeric Vinyl | Polymeric Vinyl | My Recommendation |

|---|---|---|---|

| Plasticizer Type | Short-chain plasticizers | Long-chain plasticizers | Polymeric's long-chain plasticizers are more stable, resulting in less migration and better durability. |

| Outdoor Lifespan | 1-2 years | 3-5 years (or more with high quality) | For anything beyond temporary promotions, polymeric is the safer and more cost-effective choice in the long run. |

| Shrinkage Tendency | Higher shrinkage rate, prone to edge curling. | Much lower shrinkage rate, stable dimensions. | High shrinkage leads to adhesive exposure and dirt accumulation, ruining the graphic. Polymeric minimizes this risk significantly. |

| Flexibility/Conformity | Less flexible, best for flat surfaces. | More flexible, can conform to slight curves and rivets. | For complex surfaces like vehicle graphics, polymeric is essential for a smooth, lasting application. Monomeric is mainly for flat, short-term signs. |

| Color Stability | More prone to fading/yellowing over time due to UV exposure. | Better UV resistance, excellent colorfastness for longer periods. | Good colorfastness means your reds stay red, and whites stay white, which is vital for brand consistency and professional appearance. |

| Cost | Generally more economical upfront. | Higher initial cost. | Consider the total cost of ownership. A cheaper monomeric vinyl that needs frequent replacement will cost more in the long run due to material, labor, and downtime. |

For long-term outdoor applications, a high-quality polymeric film is truly the way to go.

Why do certain colors fade or yellow more easily outdoors?

Have you noticed how some vibrant colors in outdoor vinyl graphics seem to fade or yellow much faster than others? This is a common challenge that many of my partners face, and it directly relates to the pigments and stabilizers used in the vinyl film.

Certain colors in Color Cutting Vinyl, such as red, orange, fluorescent hues, and even white, are more susceptible to degradation from prolonged outdoor exposure. Reds and oranges, along with fluorescent colors, often use pigments that are less stable when exposed to UV light, causing them to fade rapidly. White vinyl, on the other hand, can yellow over time due to UV radiation9 reacting with the PVC material itself or the plasticizers in the film.

This phenomenon is something I've studied extensively in my manufacturing role at Hangzhou Nuclear Coated Fabrics Co., Ltd. Achieving vibrant and stable colors in outdoor conditions is a complex science involving UV stabilizers10, antioxidants11, and high-quality pigments. Mr. Watford, a seasoned professional who prioritizes performance and durability, understands that not all colors are created equal when it comes to long-term outdoor use.

Here’s a breakdown of why specific colors tend to perform differently in outdoor environments, along with solutions to mitigate these issues:

| Color Category | Degradation Tendency | Cause | Mitigation Strategies |

|---|---|---|---|

| Red, Orange, Yellow | Prone to fading, losing intensity, becoming dull. | Pigments used for these colors often have lower UV stability. | Use high-quality polymeric films with enhanced UV inhibitors. Consider laminating with UV-protective overlaminates. |

| Fluorescent Colors | Very rapid fading, significant loss of luminosity. | Highly unstable pigments that absorb UV light and re-emit it as visible light. | Best for very short-term promotions where extreme visibility is paramount. Not recommended for long-term outdoor use. Laminating helps, but fading is still inevitable over time. |

| White | Tendency to yellow or become off-white. | UV degradation of PVC (oxidative yellowing) or plasticizer migration to the surface. | Opt for high-quality white films specifically formulated for outdoor use with strong UV stabilizers. Regular cleaning can sometimes help prevent surface discoloration. |

| Black, Dark Blue | Generally more stable, but can also fade slightly over very long periods. | Pigments are typically more UV stable. | While more resistant, for maximum longevity in extreme conditions, a protective laminate is still beneficial. |

Selecting vinyl products that incorporate advanced UV stabilizers and high-performance pigments is key to maintaining color consistency and graphic integrity over time, especially for mission-critical branding applications.

How is Color Cutting Vinyl applied and what is the role of transfer tape?

Are you familiar with the precise steps involved in applying Color Cutting Vinyl, especially how to accurately position intricate designs? The process often relies heavily on a crucial accessory: the transfer tape.

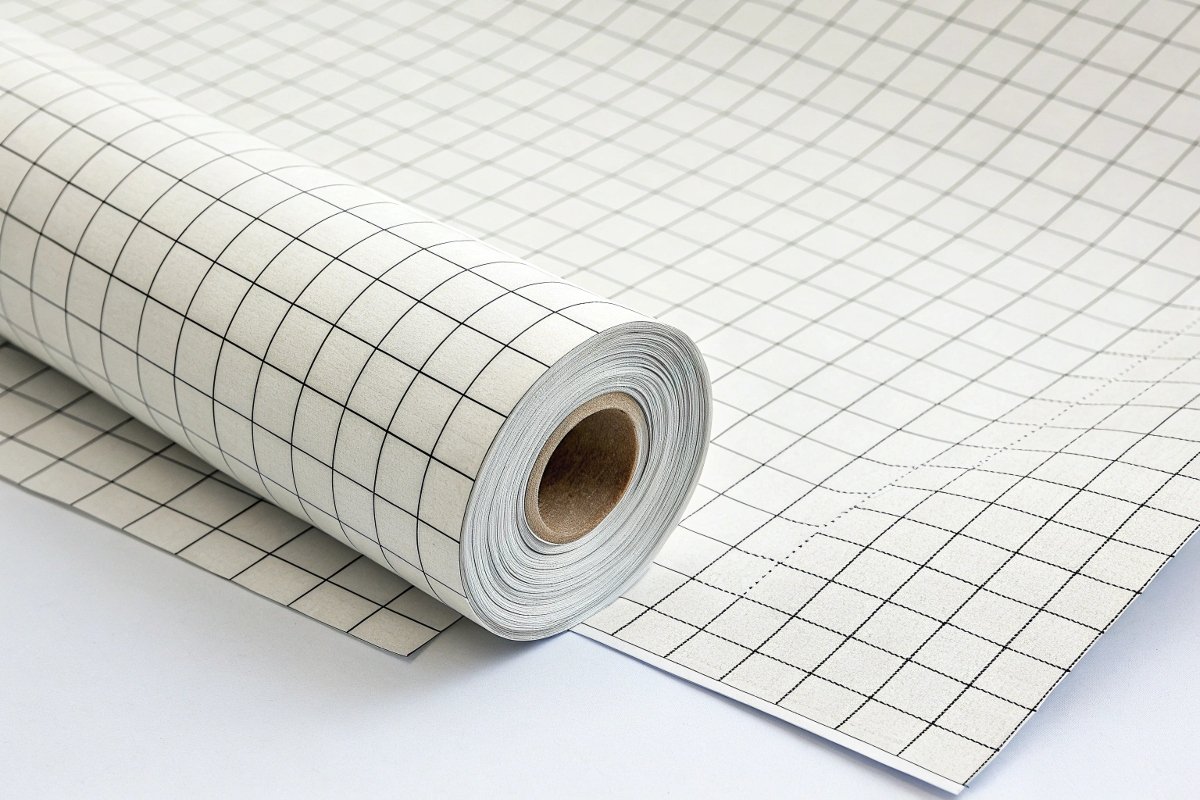

Once Color Cutting Vinyl is cut on a plotter, the excess vinyl (called "weeding") is removed, leaving only the desired graphic on the release liner. To apply this graphic accurately to a surface, a specialized transfer tape (also known as application tape12 or pre-mask) is typically used. This tape is applied to the front of the cut vinyl, lifting the design from its release liner, allowing for easy, single-piece transfer and precise positioning onto the target surface.

I often advise those I empower to start their own flex banner production facilities that proper application techniques are just as important as the quality of the material itself. It’s not enough to have a great product; you need to know how to use it effectively. Mr. Watford, with his hands-on experience in his garage workshop, understands this perfectly – he knows that even with a Roland printer, the "final touch" of application can make all the difference.

To clarify the role of transfer tape and its adhesive properties, I've outlined the different types and their primary uses.

| Transfer Tape Type | Initial Tack (Adhesion) | When to Use | My Insight |

|---|---|---|---|

| High Tack | Strong initial adhesion | Best for textured vinyls, challenging surfaces, or when transferring large, intricate designs that need a lot of grip. It ensures all small pieces lift cleanly from the liner. | High tack can be difficult to remove cleanly from the applied graphic, especially on delicate surfaces or with matte vinyls. Test a small piece first. |

| Medium Tack | Balanced initial adhesion | Most versatile, suitable for a wide range of standard vinyl films and application surfaces. This is often the go-to choice for general-purpose applications. | A good starting point for most projects. It offers enough grip without being overly aggressive during removal. |

| Low Tack | Gentle initial adhesion | Ideal for smooth vinyls, delicate surfaces (like painted walls), matte finishes, or when you need the ability to reposition the graphic during application without damaging the vinyl or surface. | Low tack is less likely to damage the vinyl surface or leave residue, which is perfect for sensitive projects. You might need to rub harder during initial application to ensure the graphic adheres. |

| Paper-Based | Varies (often medium to high) | Economical, good for general applications. Can be slightly opaque, making precise alignment a bit harder. Often tears more easily. | Good for cost-sensitive projects. Its opacity is a drawback for extremely precise placement on clear surfaces; consider a clear tape for those. |

| Clear Film-Based | Varies (often medium to low) | Essential when precise alignment on translucent or transparent surfaces is required, as it allows you to see through to the application surface. Also, generally more durable. | Clear tape is excellent for multi-layer graphics and window decals where visibility is paramount. It tends to be more expensive but offers superior precision. |

Color Cutting Vinyl also often features a grid pattern on its release liner. This grid serves as a helpful guide for measuring, cutting, and ensuring horizontal alignment during both the weeding and application processes, contributing to precise and professional results.

Why are extensibility and dimensional stability essential for plotter cutting vinyl?

Are you aware that the extensibility and dimensional stability of Color Cutting Vinyl are critical factors that directly impact the success of your plotter cutting projects? Many customers only consider the initial price, overlooking these nuances that affect both cutting precision and the final graphic’s longevity.

Extensibility refers to the vinyl's ability to stretch without breaking, which is crucial for intricate cutting operations. If the material lacks sufficient extensibility, the plotter blade can snag or tear the vinyl, especially when cutting small letters or complex designs. Dimensional stability13, on the other hand, is the material's resistance to changing its size or shape due to heat or tension. Poor dimensional stability means the vinyl might shrink or warp during cutting, causing alignment issues or making the applied graphic buckle over time, particularly in outdoor environments.

In my manufacturing venture, Hangzhou Nuclear Coated Fabrics Co., Ltd., focusing on quality polymeric materials with stable heat shrinkage rates is a cornerstone of our production. Precision and consistency are paramount. I know that Mr. Watford, with his keen eye for detail honed by years of evaluating materials from industry leaders, would scrutinize these very characteristics. A material that doesn't hold its shape means wasted material, ink, and time, completely undermining any initial cost savings.

Here’s a look at why extensibility and dimensional stability are indispensable qualities for high-performance Color Cutting Vinyl:

| Characteristic | Impact of Poor Quality | Benefit of High Quality | My Recommendation for Buyers |

|---|---|---|---|

| Extensibility | Blade snagging, tears in intricate cuts, difficulty weeding small details. | Smooth, clean cuts even for small or complex designs, easier weeding. | Test samples with your plotter on demanding designs to verify extensibility. This directly impacts cutting success and efficiency. |

| Dimensional Stability | Shrinkage/warping after cutting or over time, buckling, lifting edges, misalignment. | Retains original size and shape, applied graphics remain flat and neat, long-lasting. | For all but the most temporary applications, prioritize vinyl with high dimensional stability. Look for polymeric film types that offer superior resistance to temperature and environmental changes. |

| Cutting Precision | Imperfect cuts, inconsistent sizing, jagged edges. | Sharp, accurate cuts with smooth edges, consistent sizing across multiple pieces. | High extensibility and dimensional stability work together for superior cutting precision, reducing material waste and post-production touch-ups. |

| Ease of Weeding | Vinyl tearing during weeding, frustration, increased labor time. | Smooth, effortless weeding, even for small and intricate designs with fine details. | Good extensibility significantly reduces weeding time and effort, especially for complex jobs. |

| Application Success | Graphics stretching unevenly during application, bubbles, poor conformability. | Graphics apply smoothly, conform well to surfaces, reduced risk of bubbles or wrinkles. | When applying, good dimensional stability ensures the graphic retains its intended shape and size, which is vital for perfect alignment and a professional finish. |

By prioritizing stable and extensible materials, you invest in both the efficiency of your production process and the lasting quality of your finished graphics, aligning with Mr. Watford's fundamental principle of discovering value and managing risk.

Further readings

Micron (Micrometer): A unit of length, often used to measure film thickness, explained at Wikipedia. ↩

GSM (Grams per Square Meter): A unit of measurement for paper weight, explained at Wikipedia. ↩

Reflective Film: Learn about retroreflective materials at Wikipedia. ↩

PET (Polyethylene Terephthalate): General information about PET can be found at Wikipedia. ↩

PVC (Polyvinyl Chloride): General information about PVC can be found on Wikipedia. ↩

Plasticizer: Learn about plasticizers and their role in polymers at Wikipedia. ↩

Thermal Stability: Information on thermal stability in materials science is available at Wikipedia. ↩

Colorfastness: Learn about colorfastness in relation to material durability at Wikipedia. ↩

UV Radiation: Information on ultraviolet radiation and its effects can be found at Wikipedia. ↩

UV Stabilizers: Learn about UV stabilizers and their function in plastics at Wikipedia. ↩

Antioxidants: General information on antioxidants in materials is available at Wikipedia. ↩

Transfer Tape: See [^17] for context. ↩

Dimensional Stability: In materials science, dimensional stability refers to a material's ability to retain its original dimensions. See ScienceDirect. ↩