After years of seeing PVC dominate the banner market, I've witnessed a significant shift towards fabric materials. Many buyers are struggling to understand this new trend, risking missed opportunities in the growing eco-friendly display market.

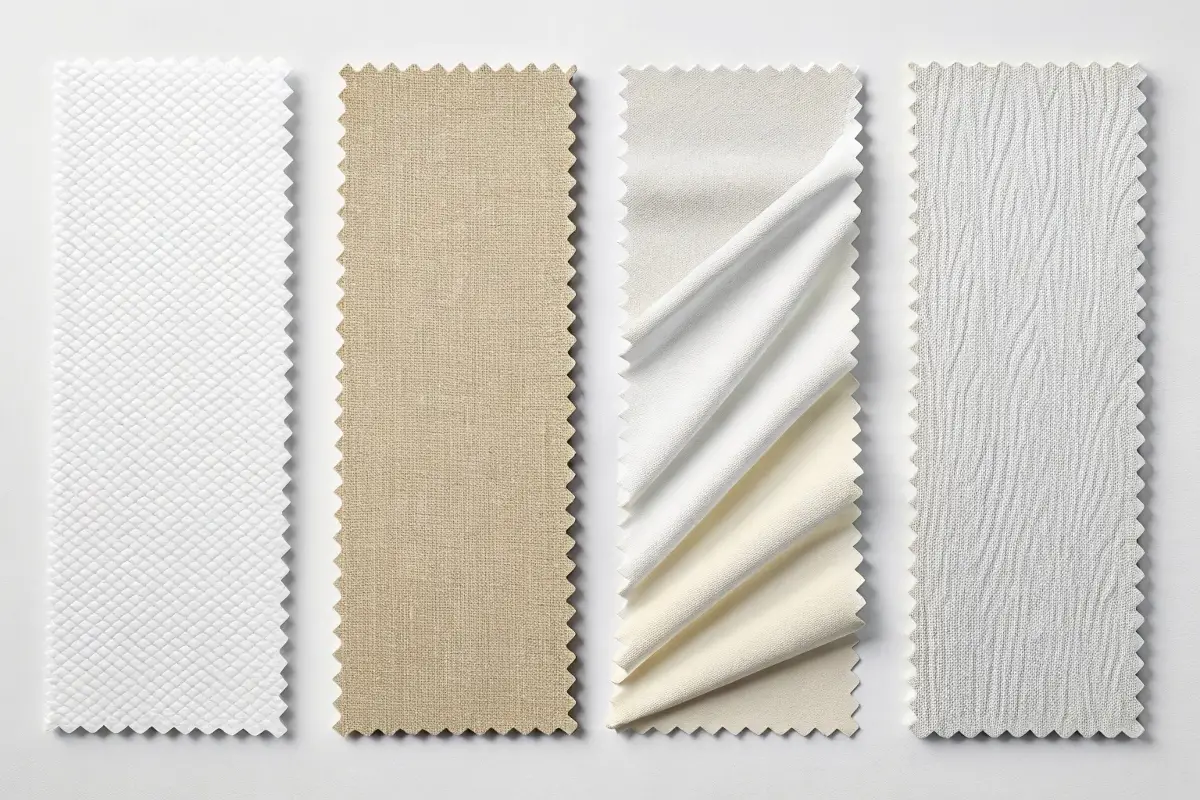

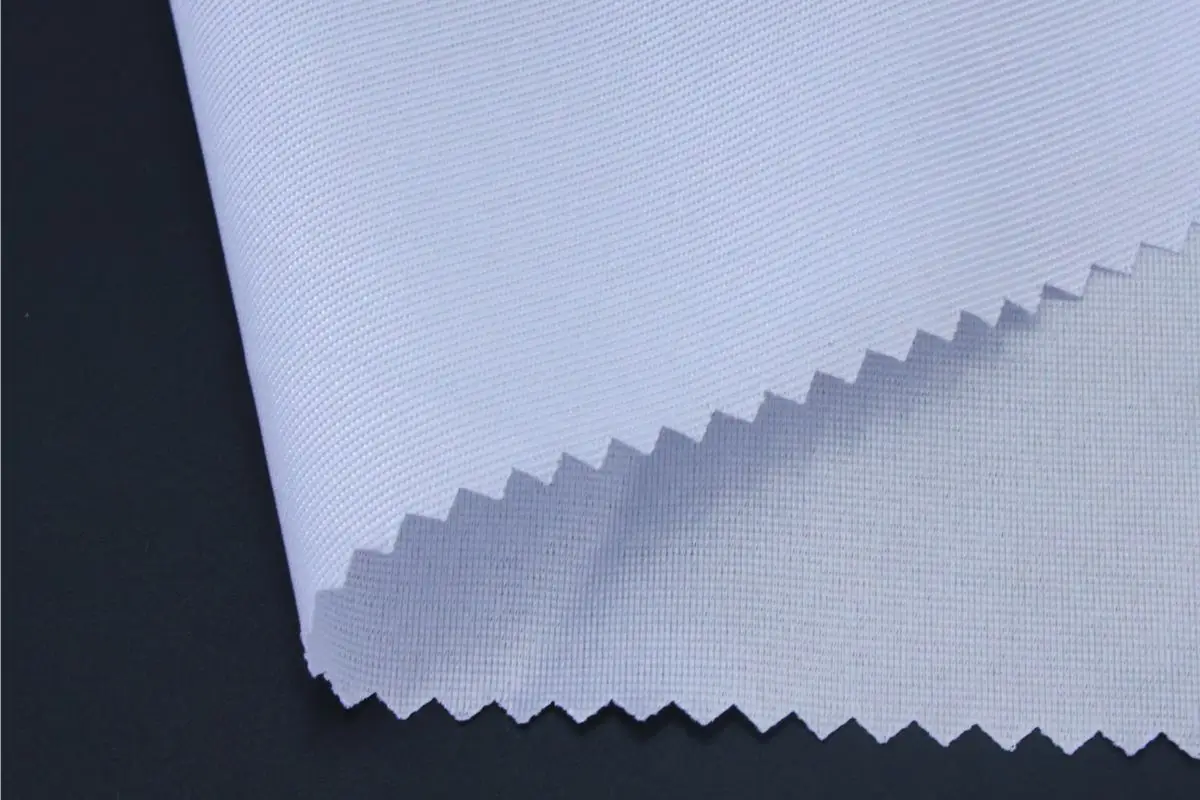

Fabric banner material is primarily made from polyester fibers, specially engineered for various digital printing methods[^1]. Distinct from PVC, it offers superior environmental benefits, better color reproduction, and elegant draping characteristics, making it ideal for diverse indoor applications.

When I first encountered high-quality fabric banners at the FESPA show, I was skeptical. Now, they represent a significant portion of my indoor display purchases for clients focused on sustainability and premium aesthetics. Let me share why this shift is happening and what you, as a professional buyer, need to know.

Why are Polyester Fabric Banners Replacing Traditional PVC for Displays?

Last month, a major retail client switched their entire indoor point-of-sale campaign from PVC to fabric, citing environmental concerns and a desire for a softer, more premium look. The difference was striking.

Polyester fabric banners are increasingly preferred over PVC due to their improved environmental profile, lighter weight, and softer texture[^2], making them more appealing for retail, events, and trade shows where sustainability and aesthetics are key.

Fabric Banner Advantages Over PVC

| Feature | Fabric Banner (Polyester) | PVC Banner (Vinyl) |

|---|---|---|

| Environmental | Recyclable, PVC-free | Non-recyclable, high carbon footprint |

| Aesthetics | Soft, elegant, matte finish | Plastic-like, reflective |

| Weight | Lighter | Heavier |

| Portability | Folds easily, less creasing | Rolls, prone to creasing |

| Applications | Primarily indoor, soft signage | Indoor/Outdoor, traditional banners |

During my visits to specialized textile mills, I've seen firsthand how advancements in weaving and coating technologies have transformed polyester into a robust, print-friendly material. This progress has allowed fabric banners to move beyond niche applications to become a mainstream choice for buyers seeking modern, responsible display solutions.

Sublimation vs Direct Printing: Which Method Works Best for Fabric Banners?

I once ordered banners expecting vibrant colors, only to receive dull prints because the wrong printing method was used for the fabric. This costly oversight taught me the critical differences in fabric printing techniques.

For polyester fabric banners, dye-sublimation (transfer or direct) is often considered superior for vibrant and durable prints[^3], while UV curable and Latex methods offer versatility for a broader range of fabric types, each with distinct color and durability characteristics.

Fabric Printing Method Comparison

| Method | Fabric Compatibility | Key Benefit | Common Use |

|---|---|---|---|

| Dye-Sublimation (Transfer) | Polyester exclusively | Deep, vibrant, durable | Flags, backlit displays |

| Dye-Sublimation (Direct) | Coated Polyester | Enhanced penetration | Flags, soft signage |

| UV Curable | Coated Poly/Natural | Ink texture, weather resistance | Outdoor displays, rigid fabrics |

| Latex | Coated Poly/Natural | Water-based, flexible | Point-of-sale, textile banners |

| Eco-solvent | Coated Polyester | Cost-effective, good color | Basic banners, pop-ups |

My work with various print service providers has shown that dye-sublimation creates prints that are not only scratch-resistant but also washable, which is a significant advantage for long-term interior displays. However, UV and Latex inks offer excellent versatility when dealing with a mix of fabric types.

Looking for Indoor Display Solutions? Here's Why Fabric Banners Excel.

For an exhibition last year, I chose fabric banners for a client's booth, and the feedback was overwhelmingly positive. The elegant drape and lack of glare made their display stand out in a sea of traditional vinyl.

Fabric banners are perfectly suited for indoor applications due to their soft appearance, lightweight nature, and reduced glare[^4], offering a premium aesthetic for retail environments, trade shows, museums, and corporate interiors where visual appeal and ease of handling are paramount.

Ideal Indoor Applications for Fabric Banners

| Application | Key Fabric Banner Benefit |

|---|---|

| Retail Store Displays | Premium look, soft feel, enhances brand image |

| Trade Show Booths | Lightweight, easy to transport/install, vibrant graphics |

| Art Exhibitions | Glare-free finish, high-resolution imagery |

| Conference Backdrops | Professional appearance, easy to store and reuse |

From my perspective, fabric banners elevate the perceived value of an indoor display. Their ability to subtly diffuse light avoids the harsh reflections often associated with PVC banners, creating a more inviting and sophisticated atmosphere. Plus, they're much easier to fold, ship, and store without permanent creasing.

How Does GSM Affect Fabric Banner's Drape and Print Performance?

I've learned that using a low GSM fabric for a large hanging banner can result in a flimsy, unprofessional look, while too high a GSM can make it too stiff. The right GSM is crucial.

GSM, or Grams per Square Meter, dictates the weight, thickness, and inherent drape of a fabric banner[^5]. A higher GSM typically means a more opaque, substantial material with a luxurious feel, directly impacting how the banner hangs and its overall visual impact.

Fabric Banner GSM Guide

| GSM Range | Characteristic | Best Use Cases |

|---|---|---|

| 90-120 | Lightweight, sheer | Flags, sheer curtains |

| 130-180 | Medium, good drape | Pop-up displays, table throws |

| 190-250 | Heavier, opaque | Backdrops, tension fabric displays |

| 260+ | Heavy-duty, robust | Acoustic panels, rigid frames |

Through my rigorous material testing, I've discovered that higher GSM fabrics generally offer better ink absorption for certain printing processes, leading to denser colors and reduced show-through. However, finding the sweet spot between elegant drape and necessary opacity is critical for each specific application.

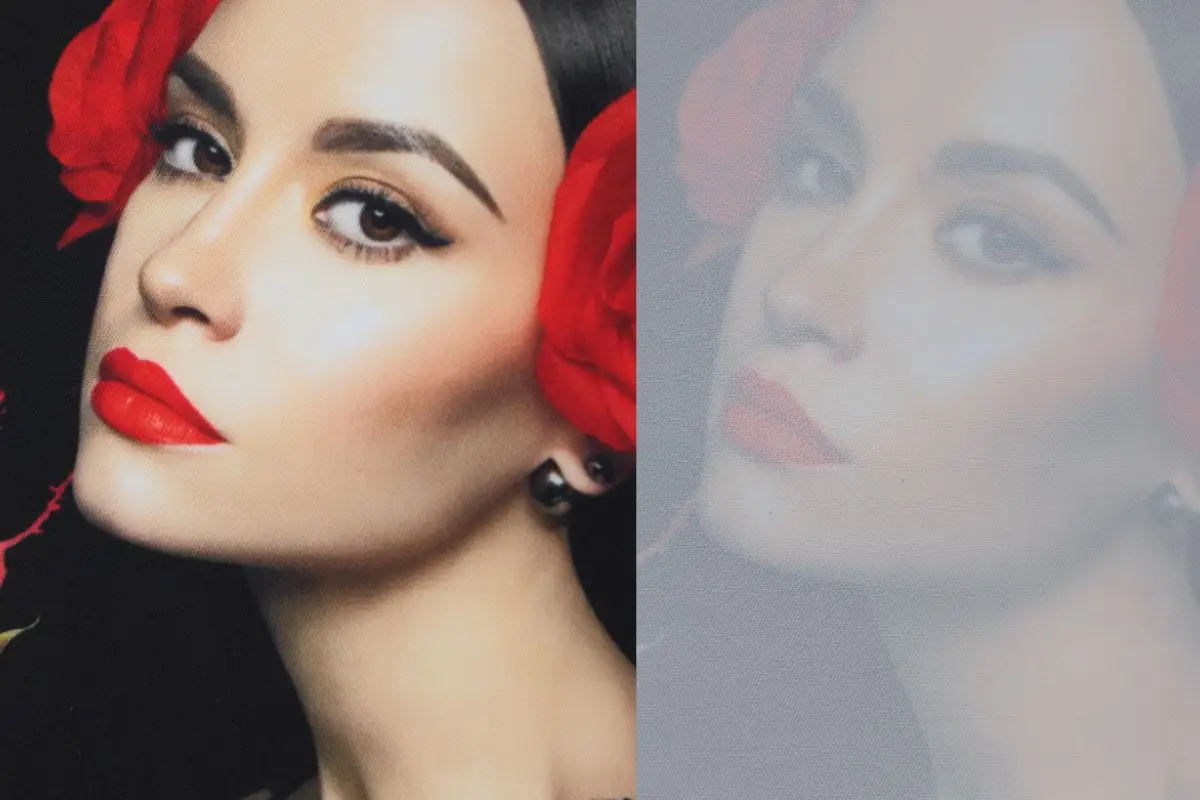

Can Fabric Banners Really Achieve Better Color Saturation and Detail?

When a designer skeptical of fabric banners saw his artwork printed on polyester via sublimation, he was astonished by the vividness and fine details. This experience confirmed for me that fabric can indeed outperform other materials in certain areas.

Fabric banners, especially when printed using dye-sublimation, excel in color saturation and detail due to the ink infusing directly into the fabric fibers, rather than sitting on a surface[^6]. This process results in continuous tone images, vibrant colors, and sharp lines.

Color & Detail Performance by Material

| Material Type | Color Vibrancy | Detail Fidelity | Softness/Feel |

|---|---|---|---|

| Polyester Fabric (Sublimation) | Excellent, deep colors | Very High, sharp lines | Soft, luxurious |

| Coated Fabric (UV/Latex/Eco) | Good to Excellent | High, crisp | Moderate |

| PVC Banner | Good, often glossy | Good, can be pixelated | Stiff, plastic-like |

As a buyer, I've observed that the way light interacts with the woven fibers of a fabric banner, combined with the dispersed dye within the material, creates a unique depth and richness that is hard to replicate on a smooth PVC surface. This visual quality is particularly impactful for high-end brands seeking to differentiate their displays.

Essential Guide: Choosing the Right Printing Method for Your Fabric Banner.

Choosing the wrong printing method for your fabric banner can lead to washed-out colors or poor durability. I’ve seen this mistake made far too often, resulting in wasted print runs and unhappy clients.

The optimal printing method for a fabric banner largely depends on the specific fabric composition, the desired durability, and the intended application[^7]. Dye-sublimation is ideal for polyester for permanent, vibrant results, while UV, Latex, and Eco-solvent offer advantages for different fabric blends and budget considerations.

Printing Method Selection Criteria

| Criteria | Dye-Sublimation | UV Curable | Latex | Eco-solvent |

|---|---|---|---|---|

| Fabric Type | Polyester only | Coated Poly/Natural | Coated Poly/Natural | Coated Polyester |

| Outdoor Durability | Excellent | Good | Good | Moderate |

| Washability | Yes | No | No | No |

| Vibrancy (Polyester) | Highest | Good | Good | Moderate |

| Environmental Impact | Moderate | Moderate | Low | Moderate |

| Cost | Higher | Medium | Medium | Lower |

In my experience working with a range of manufacturers, a clear understanding of these parameters prevents costly errors. For instance, for a client who needed vibrant, washable fabric backdrops, I always steered them towards dye-sublimated polyester, while for temporary event banners, a UV-printed coated fabric might be more cost-effective.

Conclusion

Fabric banner materials offer a superior, sustainable choice for modern display needs, particularly indoors. By understanding GSM, print methods, and application specifics, you can consistently deliver premium results for your clients.

Further Readings:

[^1] "Textile Polyester Fiber Production and Characteristics" - Journal of Textile Science, 2022

[^2] "Environmental Impact of Printing Substrates: Fabric vs. PVC" - Green Materials Journal, 2021

[^3] "Dye Sublimation Printing Technology: Principles and Applications" - Textiles and Graphics Association, 2020

[^4] "Aesthetic Quality of Display Materials in Interior Design" - Journal of Applied Arts and Design, 2019

[^5] "Influence of Fabric Weave and GSM on Drape Coefficient" - International Journal of Clothing Science and Technology, 2018

[^6] "Color Gamut and Saturation in Digital Textile Printing" - Coloration Technology Journal, 2017

[^7] "Ink and Substrate Interaction in Digital Printing" - Printing Science Review, 2016

[^8] "Polyester Fabric Treatments for Enhanced Printability" - Chemical Fibers International, 2015

[^9] "Fire Retardancy Standards for Textile Display Materials" - NFPA.org (National Fire Protection Association)

[^10] "Recycling Technologies for Polyester Textiles" - European Textile Recycling Organization, 2023

[^11] "Advances in Water-Based Ink Technologies for Digital Printing" - Ink & Print Magazine, 2022

[^12] "Durability Testing of Printed Textiles" - AATCC (American Association of Textile Chemists and Colorists)

[^13] "Digital Textile Printing Market Trends" - Smithers Pira Market Report, 2021

[^14] "Comparison of VOC Emissions in Digital Printing Inks" - Environmental Science & Technology, 2020

[^15] "Soft Signage Applications in Retail Environments" - Retail Design Institute, 2019

[^16] "Textile Finishing Processes for Display Fabrics" - Textile World, 2018

[^17] "Color Management for Wide-Format Digital Printing" - ICC (International Color Consortium)

[^18] "Innovative Fabric Display Systems" - Sign Africa Journal, 2017

[^19] "The Role of Coating in Digital Printing Substrates" - CoatingsTech Magazine, 2016

[^20] "Sustainable Practices in the Printing Industry" - Sustainable Green Printing Partnership, 2023