Are you curious about the clever material that allows people inside to see out, but restricts vision from the outside in? Many professionals, like Mr. Watford, are keen to understand the nuances of this specialized printing media.

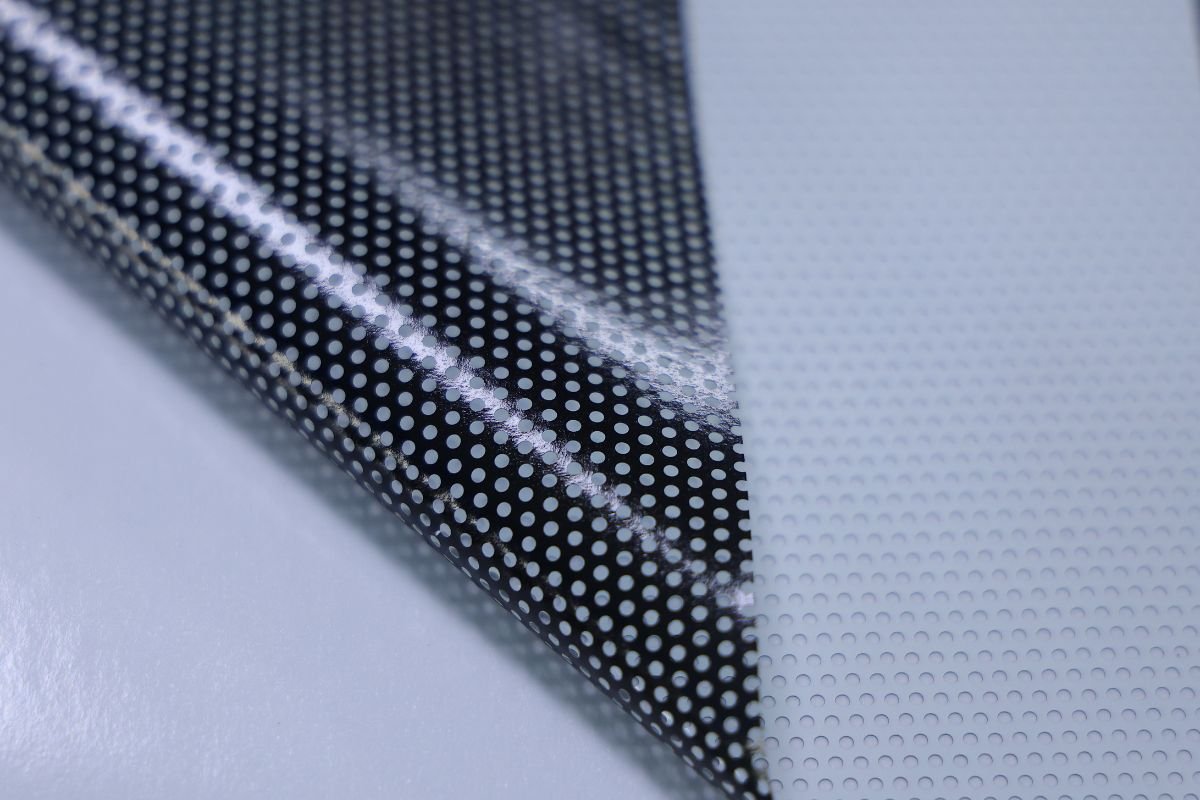

One Way Vision, also known as perforated vinyl, is a unique adhesive film designed for window graphics. It achieves its effect through a pattern of tiny holes, allowing light to pass through from one side while displaying a solid image on the other. This material typically consists of a black and white composite film, which is then perforated and laminated with a release liner.

I remember my early days at Shanghai Chungkong Ad-Mart Co., Ltd., explaining how this "magic" film works to amazed clients. It was fascinating to see their understanding grow as I detailed the science behind it. This product's ability to create privacy and effective advertising simultaneously has always made it a standout.

What are the common types and their adhesive properties?

Are you wondering about the different types of One Way Vision film available and how their adhesive properties differ? My partners often inquire about specific material configurations, especially regarding the adhesive and release liner, and how these affect application and removal.

One Way Vision films typically vary in their film thickness, release liner weight, and adhesive type. For example, a common configuration is 120 micron black and white film with a 120gsm release liner, often using a semi-removable adhesive. Other types, such as 140 micron film with a 140gsm liner or 160 micron film with a 140gsm liner, usually feature a fully removable adhesive.

When I started my international business, working with clients like Manish Aggarwal, understanding the specifics of each product was paramount. The subtle differences in adhesive strength—between "semi-removable" and "fully removable"—are crucial for effective application and, more importantly, clean removal. These terms relate to how effectively the pressure-sensitive adhesive1 can be removed from a surface over time without leaving residue. My experience has shown me that true "full removability" comes from a carefully engineered balance of initial tack and holding power.

To make these distinctions clearer, especially concerning the adhesive properties, I’ve put together a table summarizing the common configurations and their corresponding adhesive types. This helps my partners and me ensure the right product is selected for each unique project.

| One Way Vision Configuration | Film Thickness | Release Liner Weight | Adhesive Type | My Insight on Application |

|---|---|---|---|---|

| Type 1 | 120 micron | 120 gsm | Semi-Removable | Good for short to medium-term applications where clean removal is important but not ultra-critical. Initial bond is strong. |

| Type 2 | 140 micron | 140 gsm | Fully Removable | Ideal for longer-term installations requiring guaranteed clean removal, even after extended periods. |

| Type 3 | 160 micron | 140 gsm | Fully Removable | Suitable for demanding applications where durability is key, but ultimate removability is still needed. |

Semi-removable and fully removable adhesives are relative concepts. A fully removable adhesive is designed to have a lower ultimate adhesion and leaves little to no residue, even after prolonged periods. A semi-removable adhesive offers a strong initial bond but is formulated to be removed with less residue than a permanent adhesive, though some ghosting might occur over very long durations. My company, Hangzhou Nuclear Coated Fabrics Co., Ltd., ensures these properties are consistent through rigorous testing, as Mr. Watford prioritizes reliability and transparent communication from his suppliers.

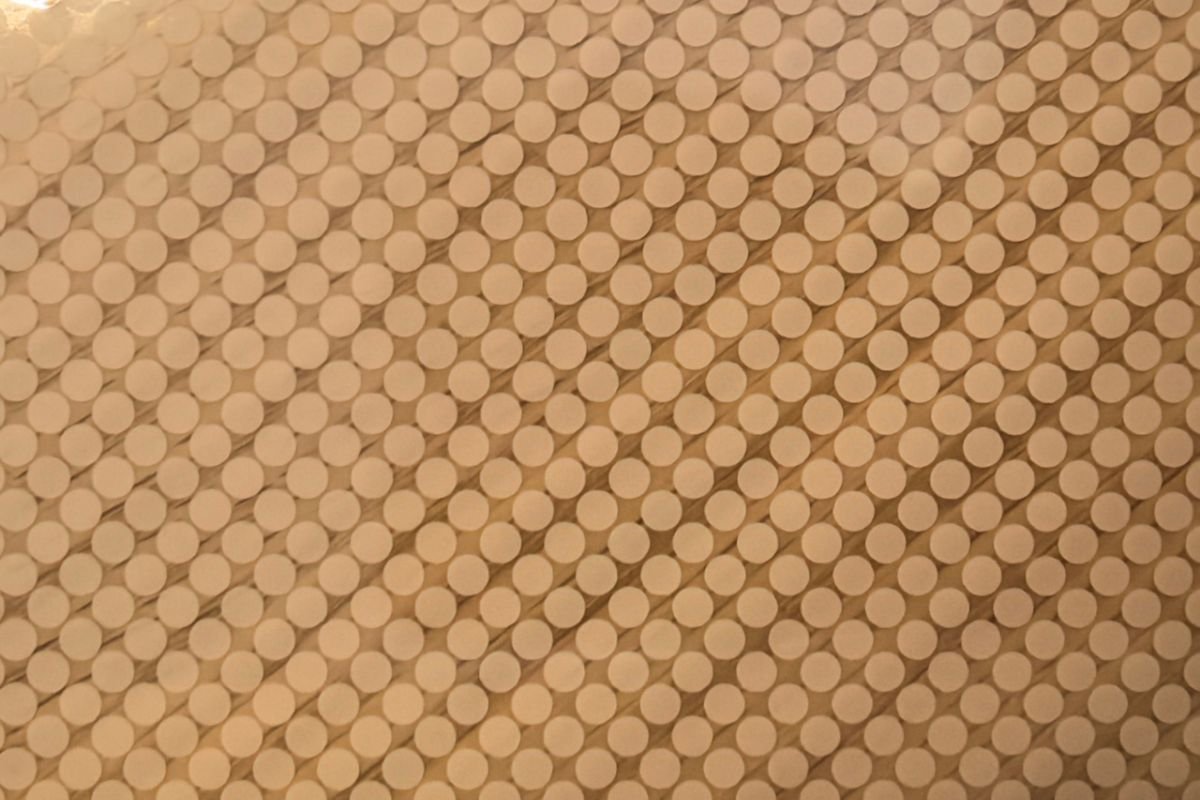

What are the standard perforation patterns and their impact on transmittance?

Are you considering how different perforation patterns affect visibility and the overall look of your One Way Vision graphics? The size and spacing of the holes directly influence the material's light transmittance, which is a key factor in its one-way effect.

Standard perforation patterns usually feature specific hole diameters and spacing, leading to distinct levels of light transmittance. For instance, a common pattern uses 1.6mm holes spaced 2.1mm apart, resulting in about 40% light transmittance. Another frequent option has 1.5mm holes with a 2.4mm spacing, offering roughly 30% transmittance.

My fascination with materials science at Hangzhou Nuclear Coated Fabrics Co., Ltd. means I’m always delving into the specifics like hole patterns. I’ve learned that these seemingly small details significantly impact how effective the one-way effect is and how vibrant the printed image appears. Custom hole diameters can also be produced, though they typically require a substantial minimum order quantity, usually exceeding 200,000 meters.

To clarify the relationship between perforation patterns and their effect on transparency and image quality, I've created the following table. This helps my partners understand how to choose the right pattern for specific applications.

| Perforation Pattern | Hole Diameter | Hole Spacing | Light Transmittance | Ideal Application | My Insight |

|---|---|---|---|---|---|

| Standard A | 1.6 mm | 2.1 mm | 40% | General advertising, vehicle windows, store fronts where good visibility is needed. | This offers a good balance between image visibility from the outside and clear viewing from the inside. |

| Standard B | 1.5 mm | 2.4 mm | 30% | More privacy-focused applications, retail displays requiring higher image density. | Provides more privacy/blockage from the outside, but slightly reduces clarity for those looking out. |

| Customized | Variable | Variable | Variable | Niche applications, specialized branding where unique visual effects are desired. | Requires significant volume (200,000m+) but allows for unique visual solutions. Discuss needs with supplier early. |

The choice of perforation pattern must consider both the desired visual effect from the outside and the required clarity for viewing from the inside. Higher transmittance means better visibility from within but a slightly less opaque image from the outside.

Why is lamination crucial for One Way Vision graphics?

Are you aware of the often-overlooked step of laminating One Way Vision graphics and why it's so critical for their longevity and appearance? Many of my clients initially focus on printing alone, but I've consistently found that lamination offers indispensable benefits.

After printing, One Way Vision graphics typically require lamination with a transparent film. This clear overlay serves multiple crucial functions. It protects the printed image from abrasion2 and environmental damage, primarily enhancing its UV resistance3 to prevent colors from fading prematurely. This lamination also helps ensure that the graphic can be removed cleanly later, protecting the underlying window surface. Without lamination, the ink can become susceptible to damage, and it can be much harder to remove the adhered vinyl cleanly.

My experience, particularly in operating my own manufacturing facility at Hangzhou Nuclear Coated Fabrics Co., Ltd., has reinforced the critical role of lamination. It's not just an optional step; it's an investment in extending the life and maintaining the vibrancy of the graphic. Mr. Watford, with his extensive experience with brands like 3M4 and Avery Dennison5, also understands the importance of material durability and performance in real-world scenarios.

To further illustrate the benefits of lamination for One Way Vision films, I’ve compiled a table outlining its key advantages.

| Benefit | Description | Impact on Graphic Performance | My Recommendation |

|---|---|---|---|

| UV Protection | Protects inks from harmful ultraviolet rays, preventing color fading. | Extends the vibrancy and lifespan of printed colors, especially for outdoor installations. | Always laminate for outdoor applications to maximize color longevity. |

| Abrasion Resistance | Shields the printed surface from scratches, scuffs, and physical wear. | Maintains the pristine look of the graphic, even in high-traffic or exposed areas. | Essential for vehicle wraps or storefronts where cleaning and contact are frequent. |

| Easier Removal | Provides a coherent layer that simplifies removal, reducing adhesive residue. | Facilitates cleaner removal from windows, minimizing glass cleaning efforts and damage. | Makes end-of-life graphic removal more efficient and cost-effective. |

| Enhanced Durability | Adds an extra layer of structural integrity to the vinyl film. | Improves overall resistance to environmental factors like rain, dirt, and temperature changes. | Increases the total lifespan and effectiveness of the One Way Vision graphic. |

| Ink Protection | Seals the ink, preventing it from leaching or being smudged over time. | Ensures consistent print quality and prevents premature degradation of the image. | Safeguards your investment in high-quality inks and printing. |

What are printer and ink compatibility considerations for One Way Vision?

Are you wondering which printers and inks are best suited for One Way Vision film, especially with the diverse range of printing technologies available today? Making the right match is crucial for achieving optimal print quality and ensuring material stability.

One Way Vision film is generally compatible with common digital printing technologies like solvent, eco-solvent, and UV curable6 inks. These inks offer excellent outdoor durability and vibrant color reproduction. However, for devices like HP Latex7 printers, specific considerations are needed due to their higher heat requirements during the curing process.

In my role overseeing manufacturing at Hangzhou Nuclear Coated Fabrics Co., Ltd., I am constantly tuned into printer technologies. I understand that printers from HP, EFI8, Epson9, and Roland10 each have unique demands on media. For instance, Mr. Watford, who extensively uses HP, EFI, Epson, and Roland equipment, needs to ensure that the vinyl's heat resistance and dimensional stability are appropriate for his specific machines.

For HP Latex printers, which use water-based latex inks and high heat to cure, it is common to use specialized release liners such as double-sided PE-coated release paper, or high-performance types like CK (clay-coated kraft) or HPL (high-performance liner11). These liners offer superior dimensional stability and heat resistance, preventing curling or warping during the printing process. Additionally, the black and white film's thermal shrinkage rate must be very stable to ensure consistent results on these high-temperature machines. Therefore, choosing the right combination of film and release liner, tailored to your printing equipment, is essential for professional, high-quality output.

What is PET transparent film used for in One Way Vision?

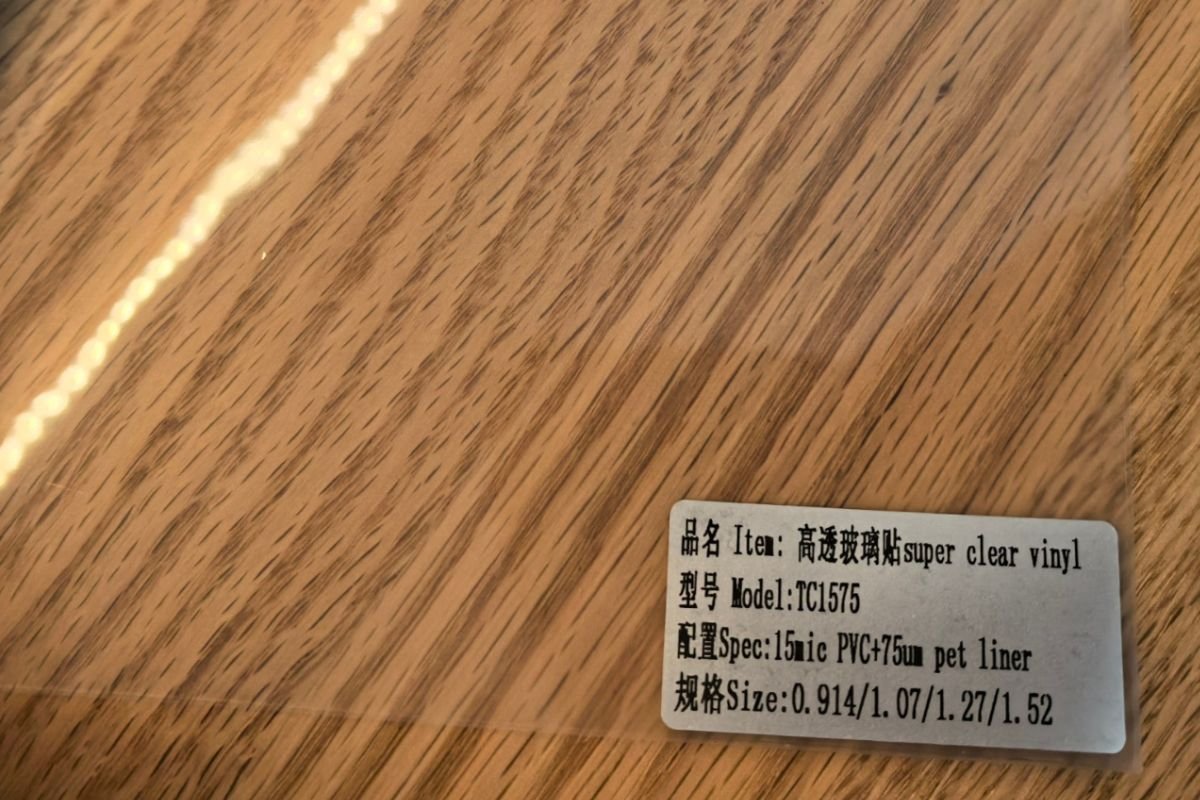

Have you ever considered an alternative approach to One Way Vision that bypasses the need for perforations entirely? There’s a specialized technique involving PET transparent film that offers unique benefits for certain applications.

Some special One Way Vision products use a clear PET12 transparent film. Instead of perforating the material, a solid white opaque layer is printed over the graphic, leaving unprinted clear dots that create the one-way effect. This method means the film is inherently unperforated and transparent in its "dot" areas, eliminating the need for punching holes.

This innovative approach is something I find quite intriguing from a materials science perspective. It effectively achieves the same visual outcome without the mechanical process of perforation. This simplifies manufacturing in some ways and can offer a smoother visual finish for the end product. My goal in providing comprehensive support to partners includes sharing these kinds of alternative solutions, helping them to explore every possible avenue for their production needs.

Here's how this PET transparent film method compares and why it might be chosen over traditional perforated vinyl:

| Feature | Traditional Perforated Vinyl | PET Transparent Film (Printed White Opaque) | My Insight |

|---|---|---|---|

| One-Way Effect Mechanism | Physical holes punched into the film. | Printed white opaque layer with clear, unprinted dots. | Both achieve the visual effect, but through different physical means. |

| Film Base | Typically PVC black/white composite film. | PET transparent film. | PET generally offers higher optical clarity and dimensional stability. |

| Perforation Process | Requires mechanical perforation after lamination. | No perforation needed; effect is created during printing. | Simplifies manufacturing by removing a step, potentially reducing complexity and cost for high volumes. |

| Need for Lamination | Usually requires lamination after printing for protection. | May not always require separate lamination if print surface is durable. | If the printed white layer is robust, it might offer sufficient protection. This needs careful evaluation. |

| Smoothness | Surface has physical holes. | Surface remains completely smooth. | A smooth surface can be preferred for aesthetics and ease of cleaning, potentially avoiding dirt accumulation in holes. |

| Transparency (Dot Areas) | Physical holes provide clear view. | Unprinted clear dots provide clear view. | Both allow inward viewing effectively. |

This PET method can also eliminate the need for subsequent lamination to achieve UV protection and ease of removal, as the durable printed white layer can sometimes serve a similar protective function. It's an elegant solution for specific applications where durability and a perfectly smooth outer surface are paramount.

How do quality control and thermal stability affect long-term performance?

Are you concerned about material quality variations and how factors like thermal stability can impact the longevity and professional appearance of One Way Vision graphics? In my experience, these are often the hidden costs that can undermine an otherwise good investment.

Ensuring consistent quality control13 and excellent thermal stability14 through the manufacturing process is incredibly important for the long-term performance of One Way Vision film. Poor quality control can lead to inconsistent hole patterns, uneven adhesive coating, or variations in film thickness, which all compromise the material's one-way effect and overall print quality. Similarly, inadequate thermal stability can cause the film to shrink or distort, especially when exposed to varying temperatures over time.

At Hangzhou Nuclear Coated Fabrics Co., Ltd., our focus on materials science extends deeply into quality assurance. My team and I put significant effort into ensuring that our coated technical textiles maintain stringent quality standards. This includes meticulous testing for temperature resistance and dimensional stability – issues that Mr. Watford, in his discerning procurement roles for Signarama15 and FASTSIGNS16, would undoubtedly prioritize. A thermally unstable film, for instance, might cause a perfectly installed graphic to warp or lift at the edges on a hot sunny day or during a cold winter night, resulting in an unprofessional look and customer dissatisfaction.

To highlight these critical aspects, I've outlined the impact of rigorous quality control and thermal stability on One Way Vision's performance, which are essential considerations for any professional buyer.

| Factor | Impact of Poor Quality/Stability | Benefit of High Quality/Stability | My Recommendation |

|---|---|---|---|

| Hole Consistency | Uneven one-way effect, degraded image clarity. | Uniform one-way effect, sharp and clear printed image. | Always demand consistent hole patterns to ensure a professional and functionally effective graphic. |

| Adhesive Consistency | Blotchy adhesion, bubbles, difficult removal, residue. | Smooth, even adhesion, clean removal, no residue. | Inquire about adhesive application methods and ensure uniform coating for reliable performance. |

| Film Thickness | Inconsistent print results, variable durability. | Uniform print quality, predictable durability. | Request thickness specifications and confirm they meet industry standards. |

| Thermal Shrinkage | Warping, curling, lifting edges, graphic distortion. | Stable dimensions, excellent resistance to temperature fluctuations. | This is crucial for outdoor graphics. Look for suppliers who provide data on thermal stability. |

| Long-Term Adhesion | Premature peeling, graphic fall-off, costly re-applications. | Secure long-term bond, graphic stays in place as intended. | Test samples for adhesion over time in real-world conditions relevant to your application. |

A truly reliable supplier provides detailed specifications and consistently delivers products that meet those standards. This proactive approach helps my partners fulfill Mr. Watford’s expectation for reliability and robust contingency planning, ultimately ensuring client satisfaction and project success.

Further readings

Pressure-sensitive adhesive: Learn more about pressure-sensitive adhesives at Wikipedia. ↩

Abrasion: General information about abrasion and wear resistance can be found at Wikipedia. ↩

UV Resistance: Learn about UV degradation and resistance in materials at Wikipedia. ↩

3M: Learn more about 3M and its materials science innovations at 3M.com. ↩

Avery Dennison: Explore Avery Dennison's specialty materials and solutions at AveryDennison.com. ↩

UV Curable Ink: Learn about UV curing and UV inks at Wikipedia. ↩

HP Latex Printers: Find more information on HP Latex printing technology at HP.com. ↩

EFI: Learn about EFI's digital printing solutions at EFI.com. ↩

Epson Printers: Explore Epson's range of professional printing solutions at Epson.com. ↩

Roland DGA: Discover Roland's wide-format printers and plotters at RolandDGA.com. ↩

Release Liner: Learn more about release liners at Wikipedia. ↩

PET (Polyethylene Terephthalate): General information about PET can be found at Wikipedia. ↩

Quality Control: Learn more about the principles of quality control at Wikipedia. ↩

Thermal Stability: Information on thermal stability in materials science is available at Wikipedia. ↩

Signarama: Learn more about the Signarama franchise at Signarama.com. ↩

FASTSIGNS: Explore the FASTSIGNS franchise network at FASTSIGNS.com. ↩